No Die & Plate Charge

6 Days Turnaround

Free Shipping

FREE Custom Designing

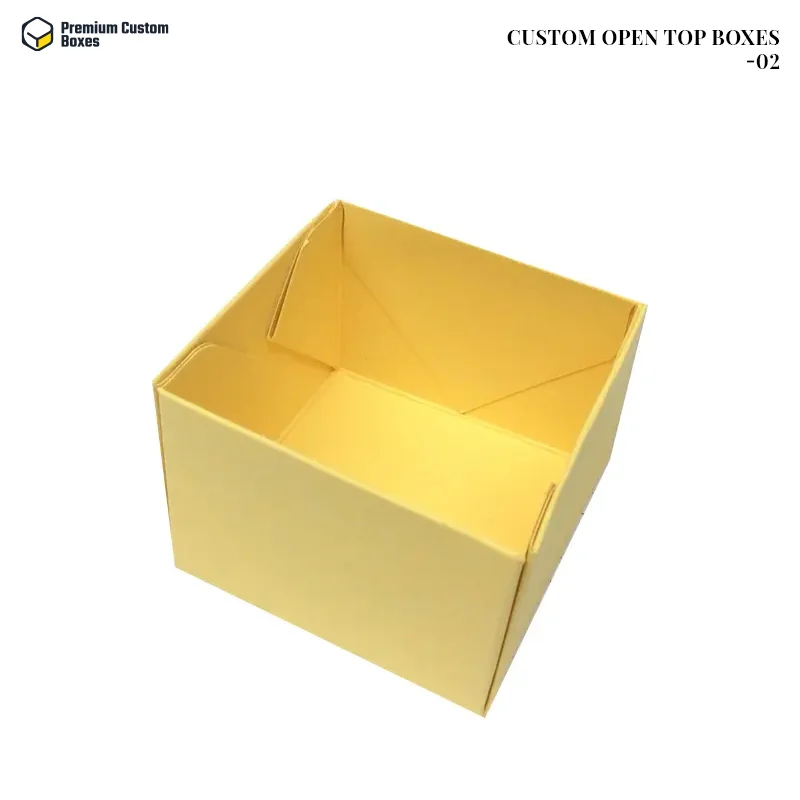

Custom Open Top Boxes

Request Custom Quote

You might feel stuck with finding custom open top boxes to carry your bulky and lightweight items, or a fancy-looking box for an effective shop display. Some even just need such a box for domestic plant decoration.

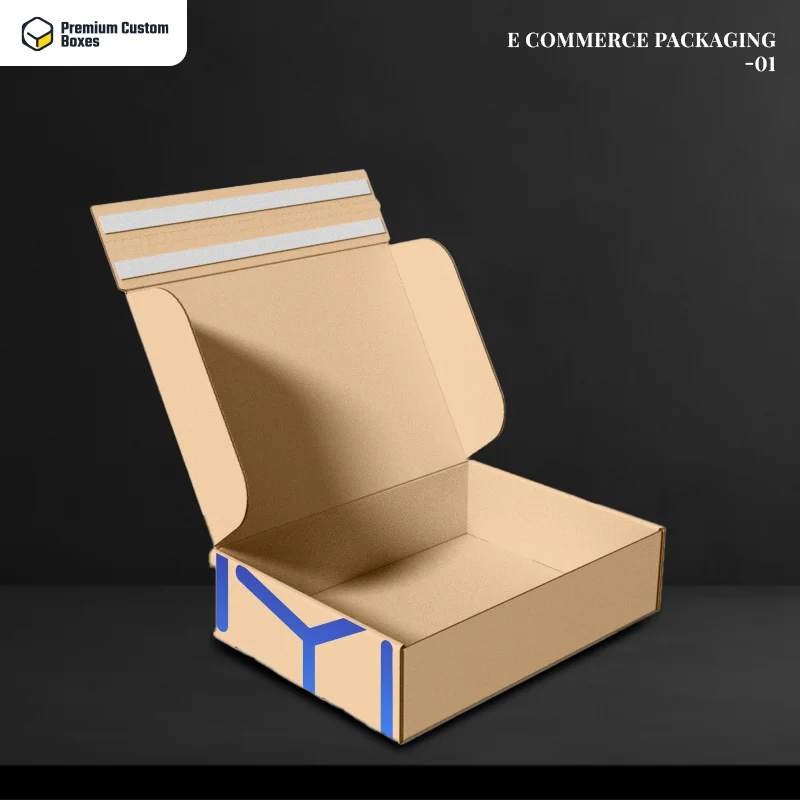

Within the e-commerce sector, these boxes are usually used for easy loading or unloading activities while keeping weight-carrying international standards in check. Most clients opt for them due to their simple assembly and portability features.

What are Open Top Boxes?

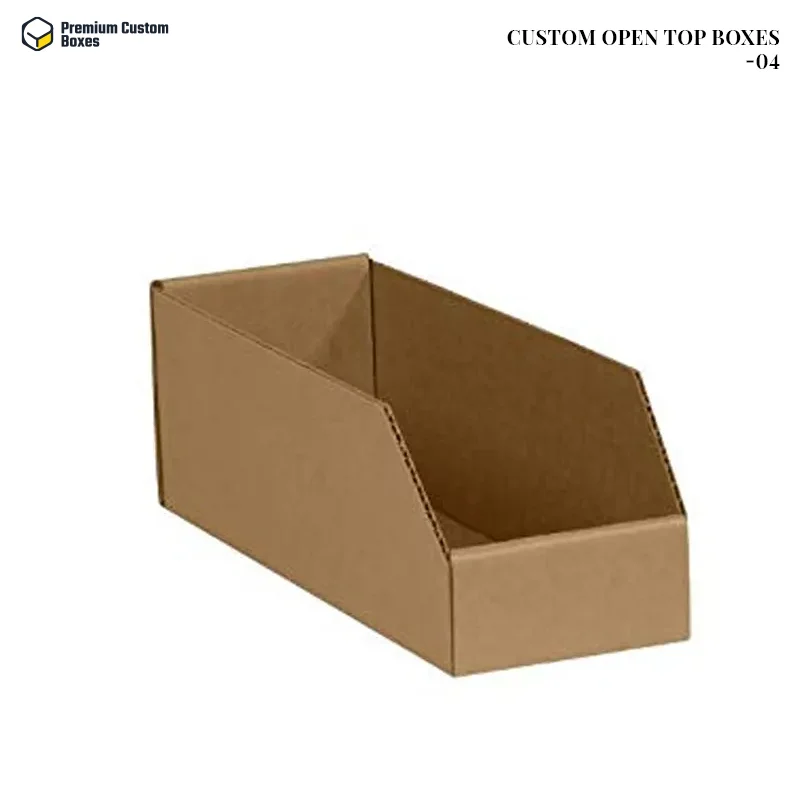

The open top boxes are what their name implies, i.e., they have their mouth wide open with sturdy sides and a bottom. Sometimes referred to as a half box, retail businesses use them to place luxury items over the counter to facilitate customers’ shopping experience. They are also actively used in managing inventory or even as fancy bins in workplace environments.

Uses of Custom Open Top Boxes

The custom open top boxes cover a wide range of utilities around various domains due to their secure, durable, and sustainable nature. Generally, the following companies actively use these boxes:

- The construction or logistics companies

- Official workplaces

- Food packaging companies

- Companies encouraging green alternatives

- Metal part packaging companies

- Point-of-sale display shops

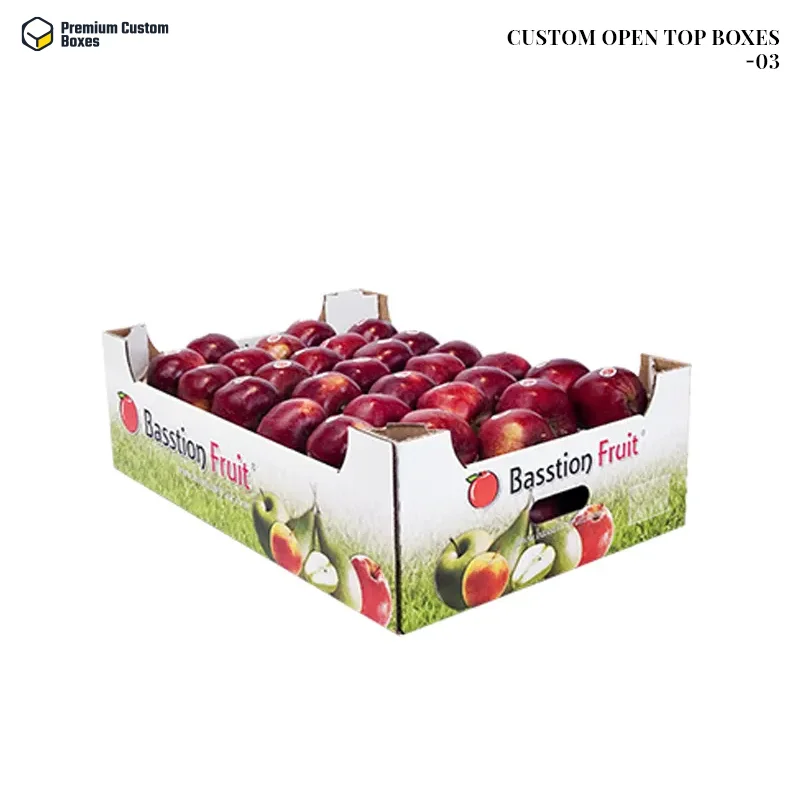

The Retail Industry

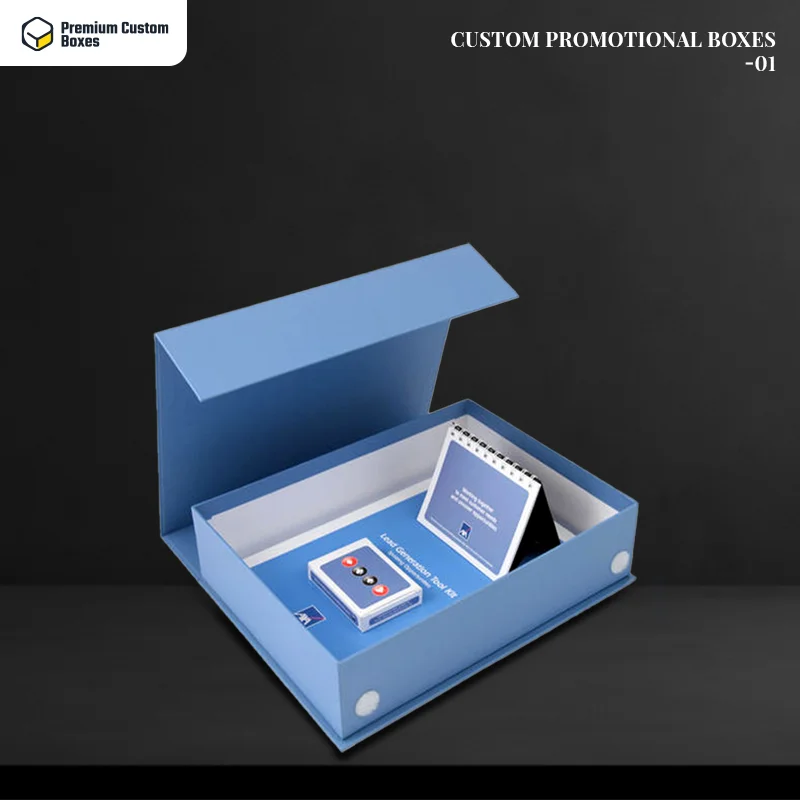

The retail sector prioritizes shelf or counter display boxes that perfectly showcase their cosmetic or luxury products, making them easily accessible to window shopping customers. During promotion season, their demand becomes all the more necessary.

The Wholesale Industry

The wholesale sector deeply cares about ease of access and pickups while delivering goods over longer distances. If your business deals with safe transfer and storage of lightweight to medium-weight mechanical parts or any other bulk transport, our open top boxes wholesale will work best for you.

The Design Guide

Our customization and design process involves the following steps to make a custom open top box:

Formation of Flat Sheets

The first step is selecting material like kraft or cardboard to form a flat sheet made from sustainable wood pulp. Clients can also choose from non-sustainable alternatives that may provide better durability.

Rectangular Custom Cutting

The flat sheet is then cut into precise rectangular dimensions using high-end die-cutting machines as requested by the client. We do not charge any separate die-cut or plate charges.

Box Folding and Assembly

After the custom rectangular pieces are printed with a custom logo design and special effects added, the box is folded on all four sides to assemble an open-top box.

Seam or Tear Test

The final step involves using various quality tests that can assess any potential seam or tear over the box’s surface before we dispatch it to our clients.

Coated Vs. Uncoated Open Top Boxes

Special coatings are applied on the printed open top boxes to improve protection, durability, and moisture resistance of the package. This additional step is crucial to enhancing brand recognition and the shelf value of your product, especially if you are going to use open top style for retail packaging.

| Coated Custom Open Top Box | Uncoated Custom Open Top Box |

| Well protected | Poorly protected |

| Improved durability | Durability compromised |

| No damage during transport | Risk of damage during transport |

| Long-lasting print | Print wears out over time |

| Better hygiene safety | Normal hygiene safety |

| Better moisture resistance | Poor moisture resistance |

| Reputable brand image | Brand image compromised |

Transit Considerations

We recommend that when customizing printed open top boxes, our clients keep certain considerations in mind to ensure a successful delivery venture with their customers. These points will help you to surpass your competitors with ease:

- Provide ample cushioning or padding within the open top box

- Avoid unnecessary space to improve the transport budget

- Shrewdly select transit paths to avoid needless delays

We Support Quality And Eco-friendliness

We value both our clients and their customers’ values, which is why our packaging company offers the most functional and aesthetic design options. We continuously test our custom open top boxes using strength tests like the drop test and Edge Crush Test (ECT) for quality assurance.

Additionally, our packages are made of wood pulp obtained from sustainable forests to address the environmental concerns of your customers. Our boxes contain material and coatings that are both recyclable and biodegradable in nature, and can decompose in allocated commercial sites without contamination issues.

Buy Now!

Made up your mind to get custom open top boxes? Get a quotation now from Premium Custom Boxes where we provide free design support and all packaging services at affordable prices. Our support team is available online to assist you throughout the design process. Let’s start packaging now!

Can I order custom open top boxes in bulk?

Yes, bulk orders can be arranged by directly placing an order on the product’s page after setting the required quantity.

Can I customize a non-rectangular open top box?

You can upload any size and shape design on the design submission page before officially placing an order. Then our design team will reach out to you for further consultation.

What is the MOQ of custom open top boxes?

Custom open top boxes at Premium Custom Boxes have no minimum order quantity. Our clients can order as many packages as they want.

Are sustainable open top boxes more popular these days?

Yes, the sustainable open top boxes are generally more popular among customers these days due to their negligible impact on climate change.

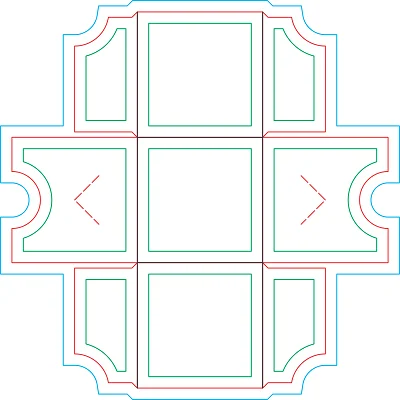

Artwork Preparation Guide

Preparing artwork for various purposes, whether it's for print, digital media, or other applications, requires attention to detail and adherence to specific guidelines. Here is a general artwork preparation guide that you can follow:

Cutting Line (Red Lines):

Indicates the cut at its final size.Important artwork and text should be placed at least 0.125 inches inside of the cutting line.

Bleed Area (Blue Lines)

Indicates where the bleed line is located. Any artwork which goes to the cutting line should be extended to the bleed line to get a seamless print.

Safe Area (Green Lines):

Indicates where artwork and text should safely be placed inside. As a industry standard, all artwork should at least be placed 0.125 inches away from the cutting lines unless your design in intentional.

Perforation Lines (Red Lines)

Perforation line refers to paper that is punched with very small holes to allow the paper to be torn and folded easily.

Creasing Line (Black Lines)

Indicated where the product is to be folded.

01

Choose Your Box

Start by browsing our extensive range of box styles and designs. Whether you're in the market for something simple and classic or intricate and bespoke, we've got a multitude of options to suit your needs.

02

Customize the Design

Once you've chosen a box style, it's time to make it uniquely yours. Upload your design or collaborate with our in-house design team to craft a packaging solution that resonates with your brand's aesthetic and vision.

03

Select Materials and Finishes

Our platform allows you to pick from a variety of materials, be it eco-friendly options, premium finishes, or durable structures. Enhance the tactile experience with finishes like matte, gloss, embossing, or specialty textures.

04

Review and Approve

Before we move to production, we'll send you a digital proof or a physical sample upon request. This ensures you're 100% satisfied with the design and materials chosen. Review, make any necessary changes, and give us the green light when you're ready.

05

Production Begins

Once you've approved the design, our team gets to work. With state-of-the-art machinery and a dedicated workforce, we ensure that each box is crafted to perfection, adhering to the highest quality standards.

06

Shipment and Delivery

With our efficient logistics network, we guarantee timely deliveries. As your boxes are packed and prepared for shipment, we'll provide tracking details to keep you informed every step of the way. Sit back and wait for your premium packaging to arrive at your doorstep.

Cardboard

Corrugated

Kraft

Rigid

Anti Scratch Lamination

Aqueous Coating

Lamination

Silk Lamination Cards

Soft Touch Coating

Spot UV

Gloss Lamination

Gloss Varnish

Matt Lamination

Matt Varnish

Debossing

Embossing

Foil stamping

Window Patching

Customer Reviews

Reviews

Great company to work with... my boxes arrived safely.

Excellent product quality and fast delivery. Highly recommended!

Good value for money. The product meets all my expectations.

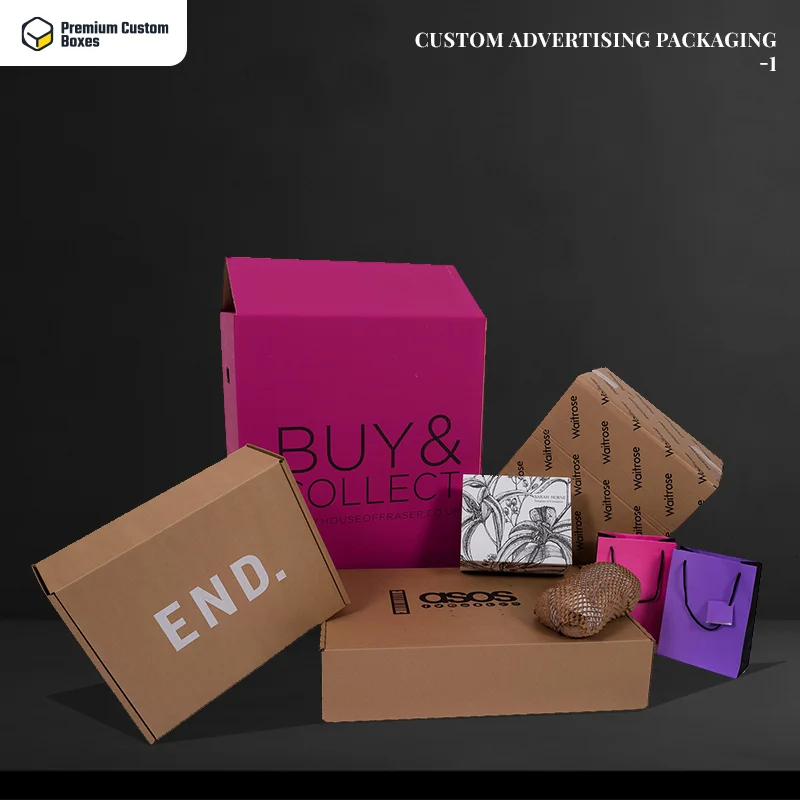

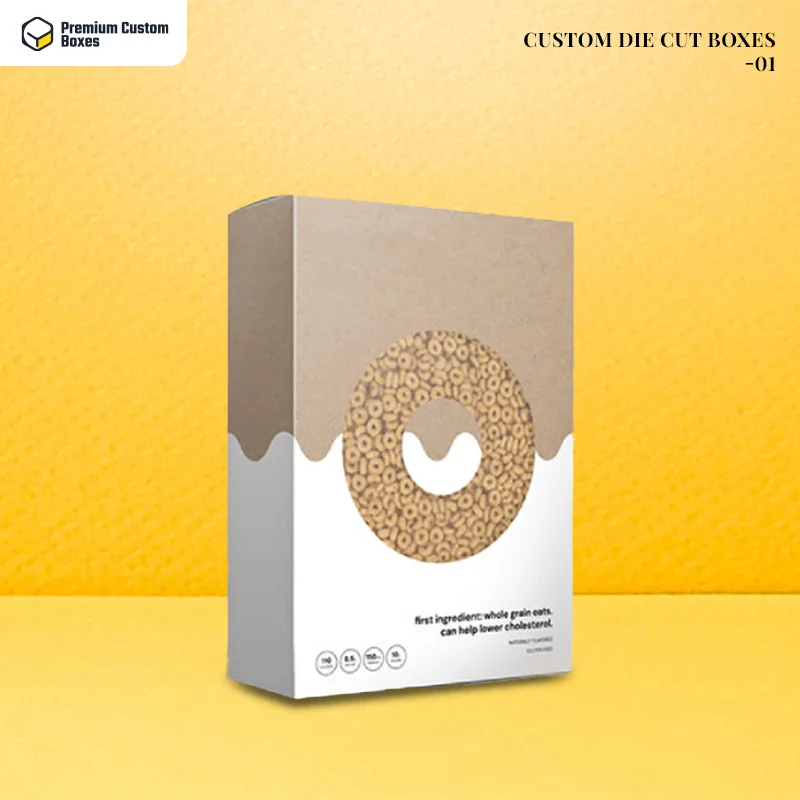

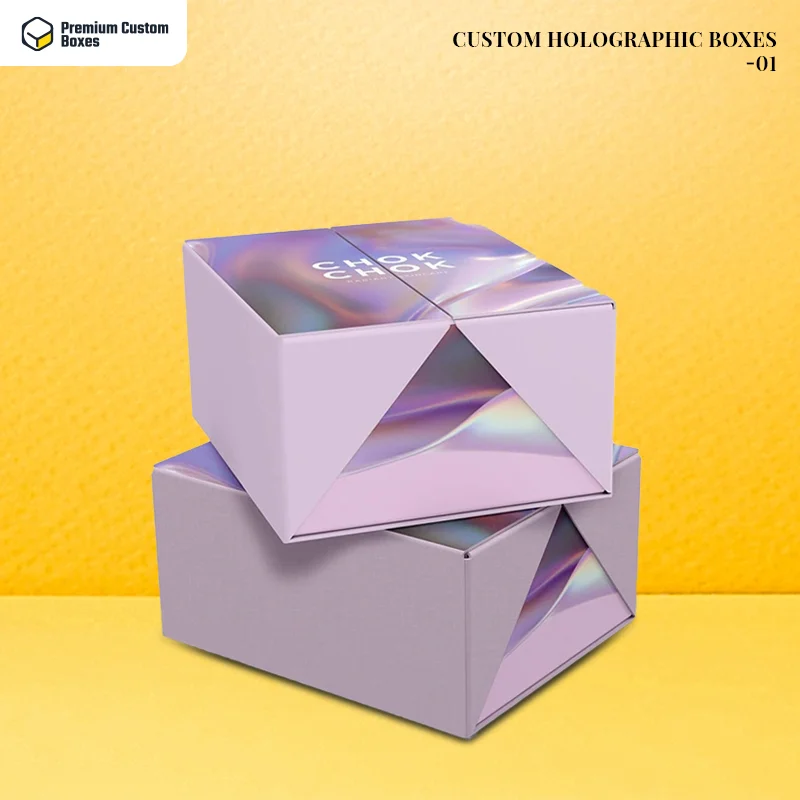

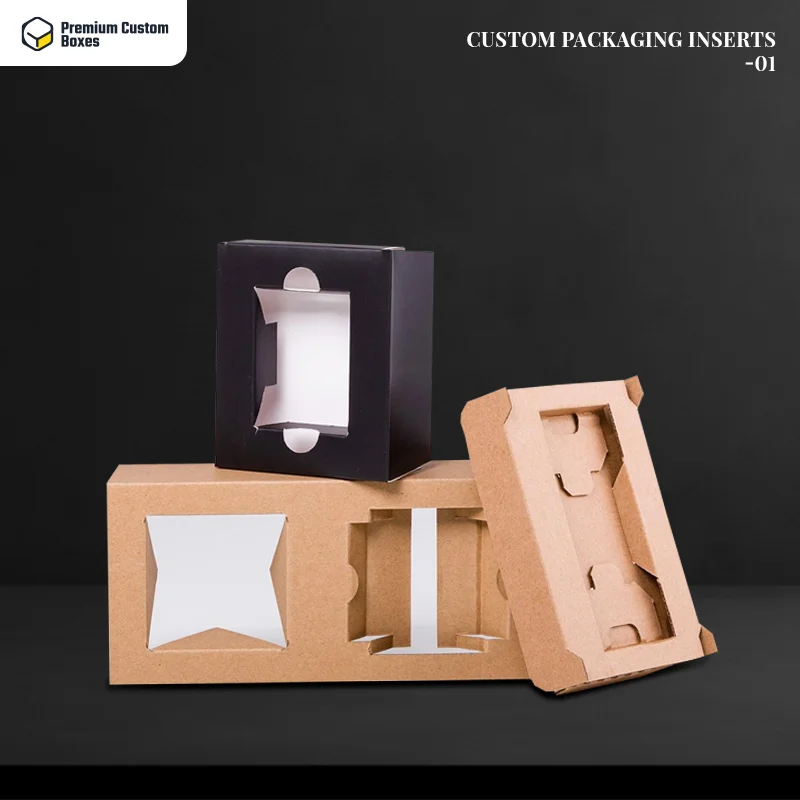

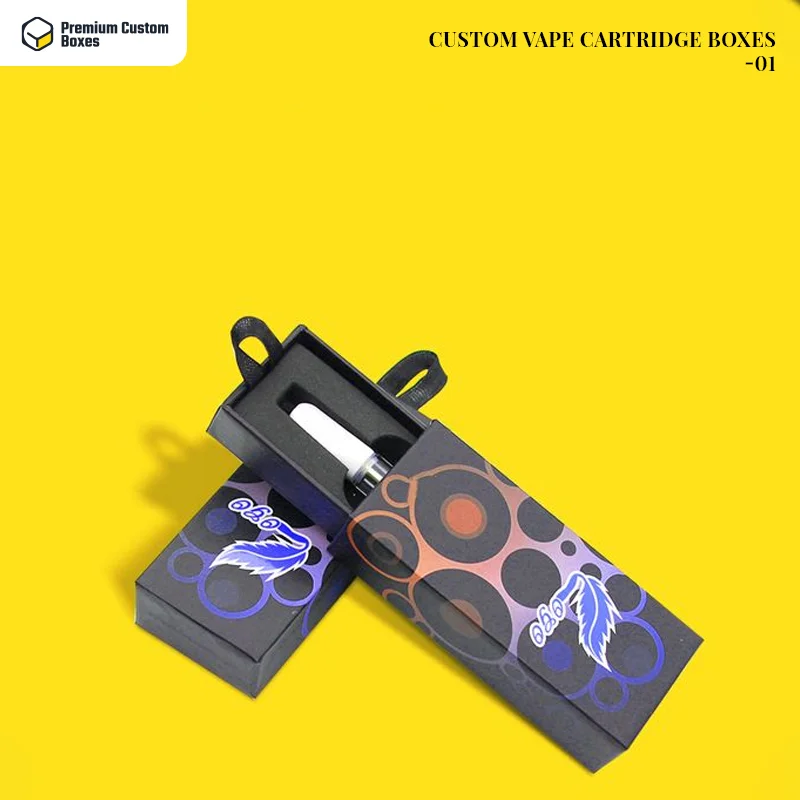

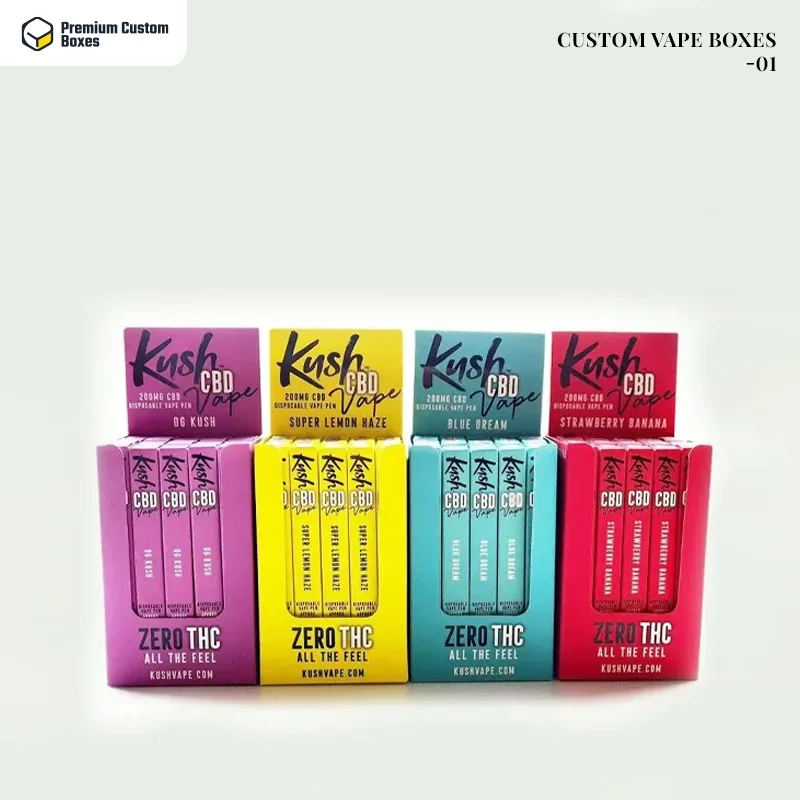

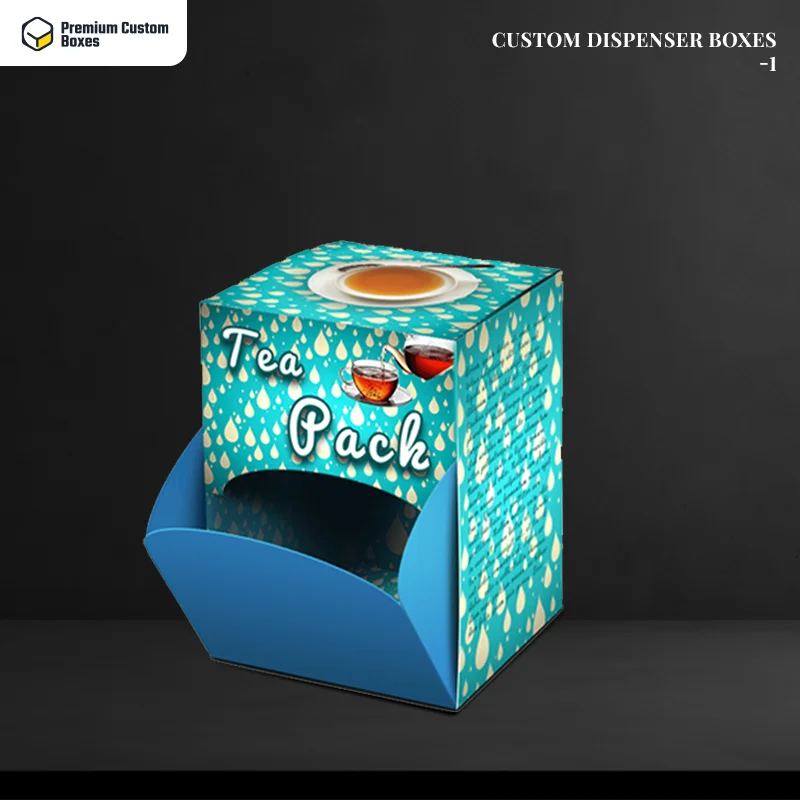

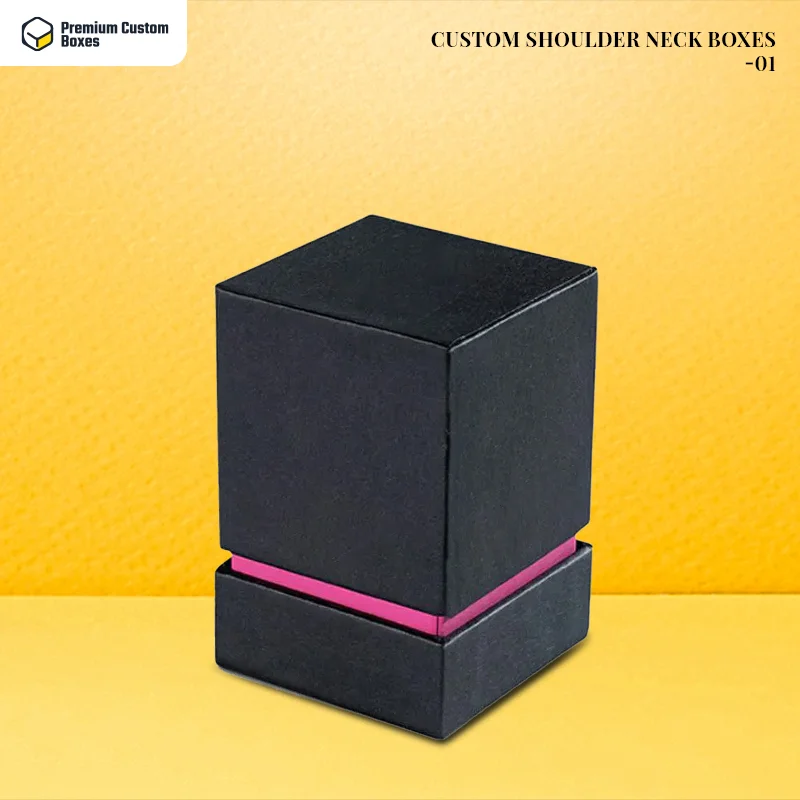

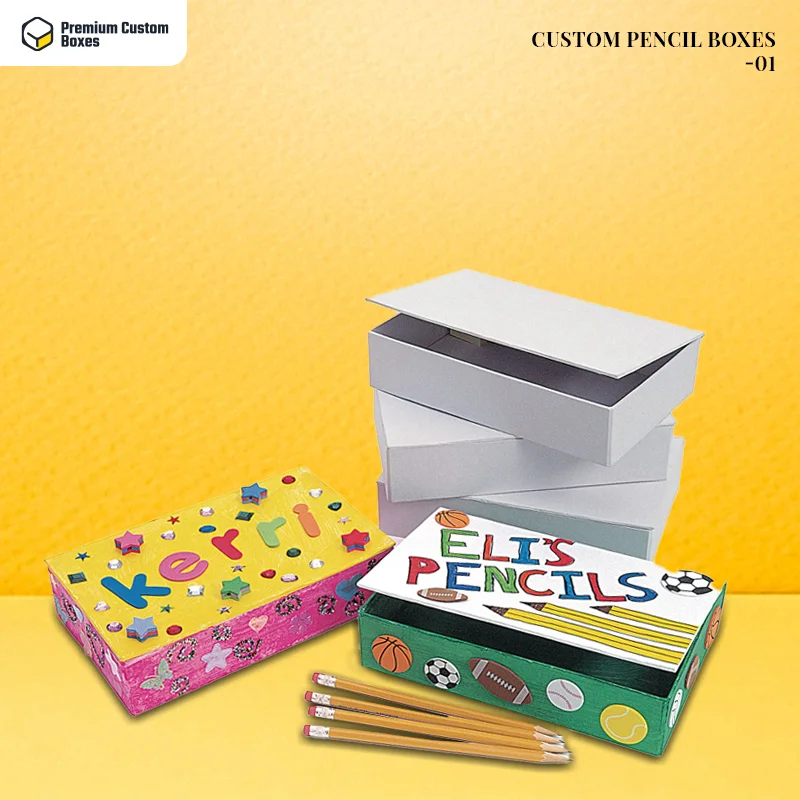

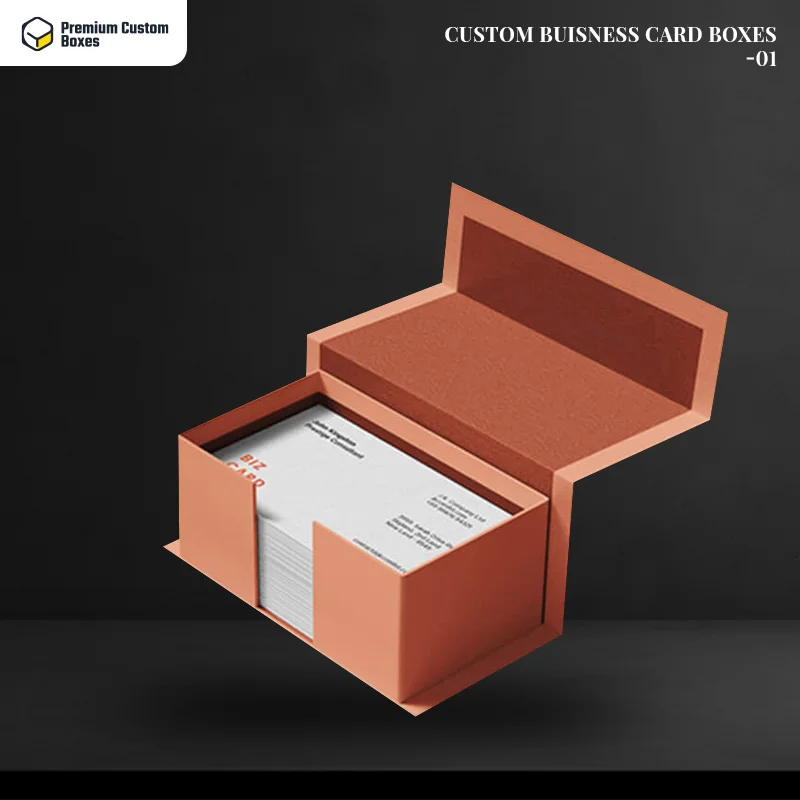

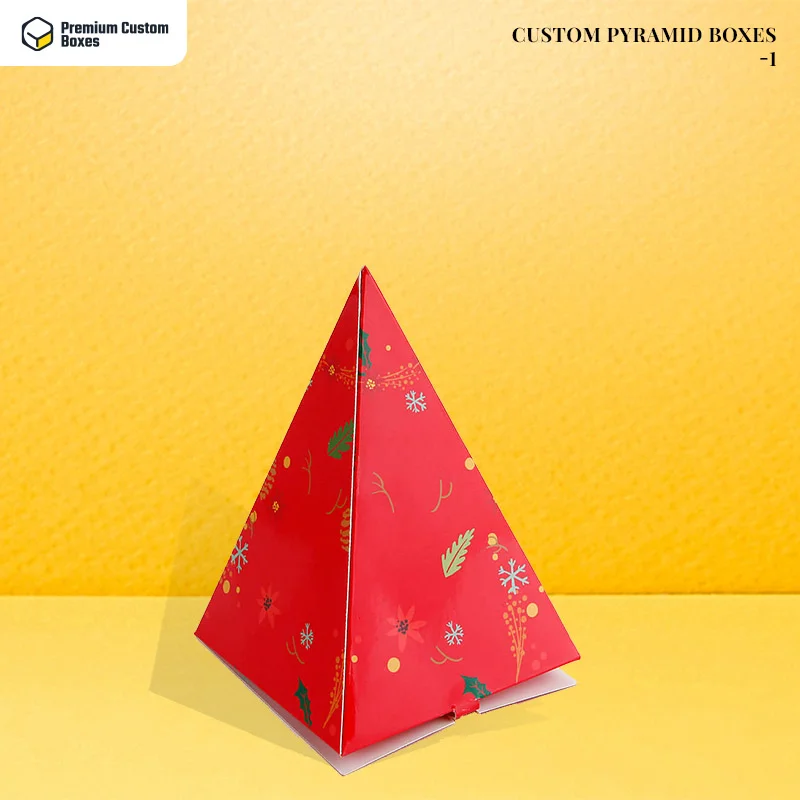

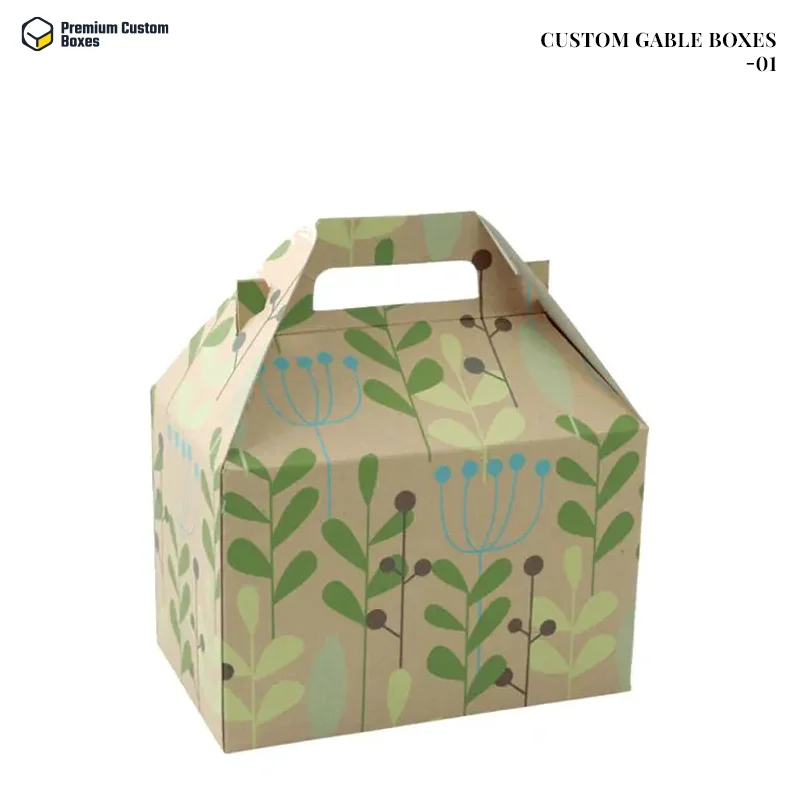

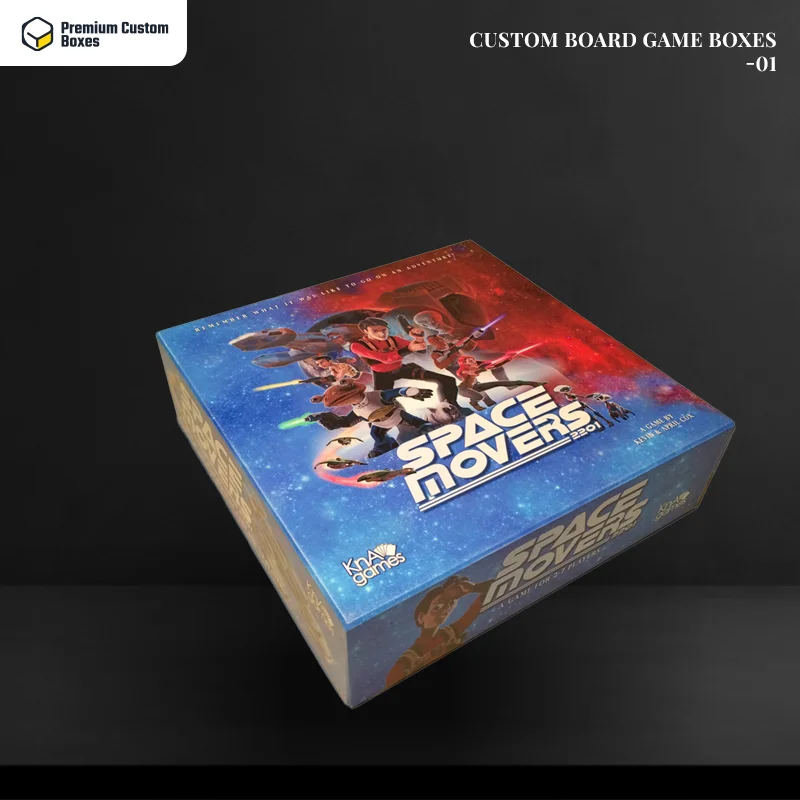

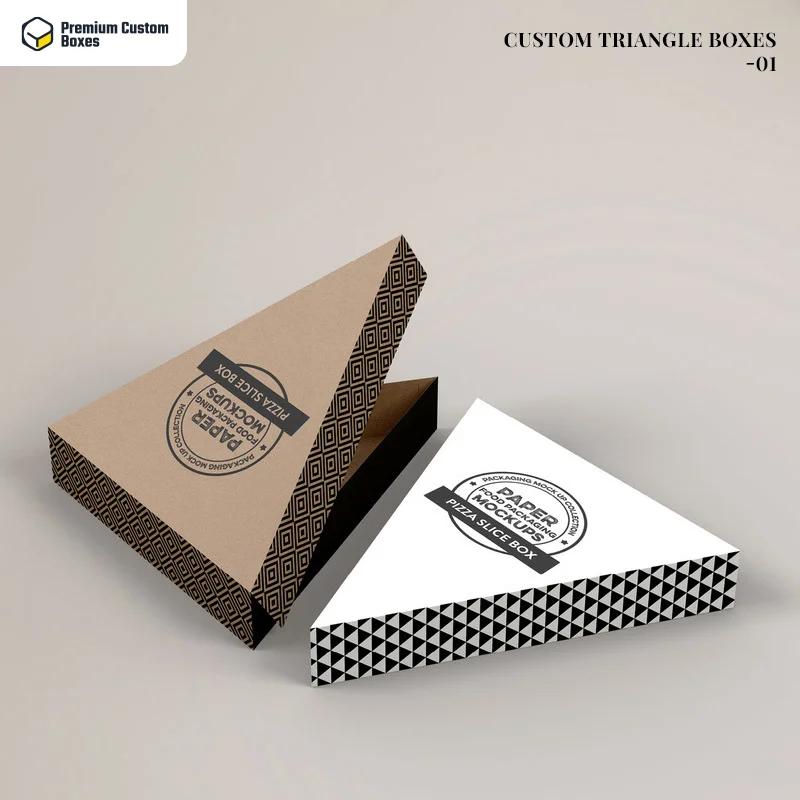

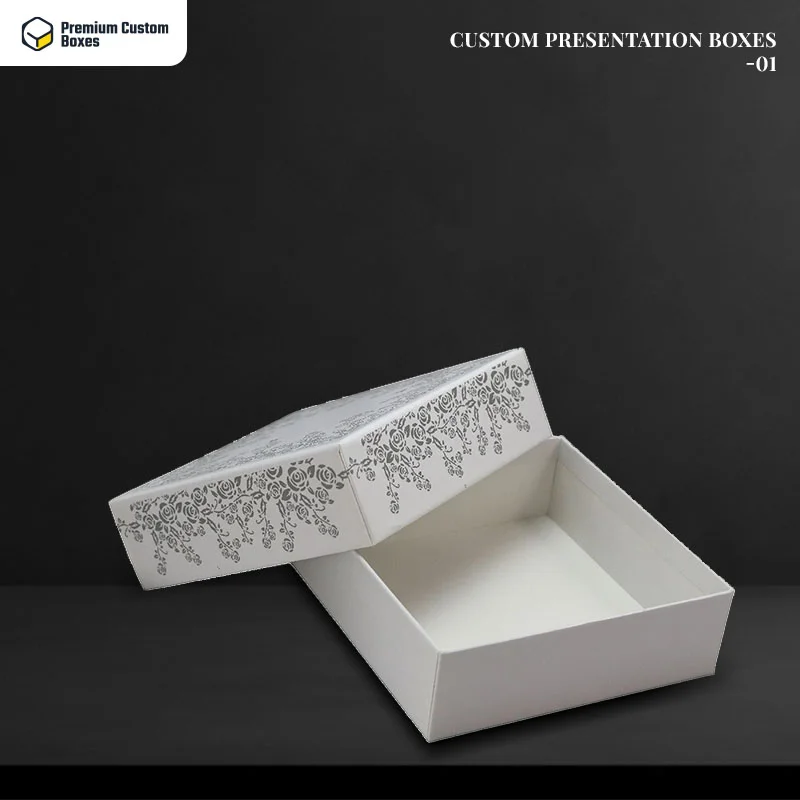

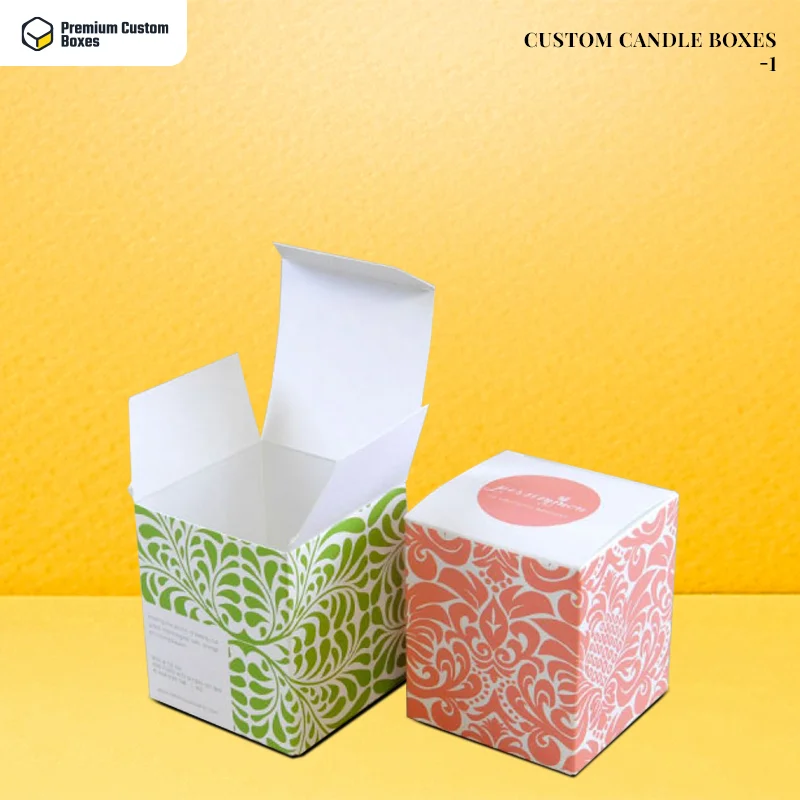

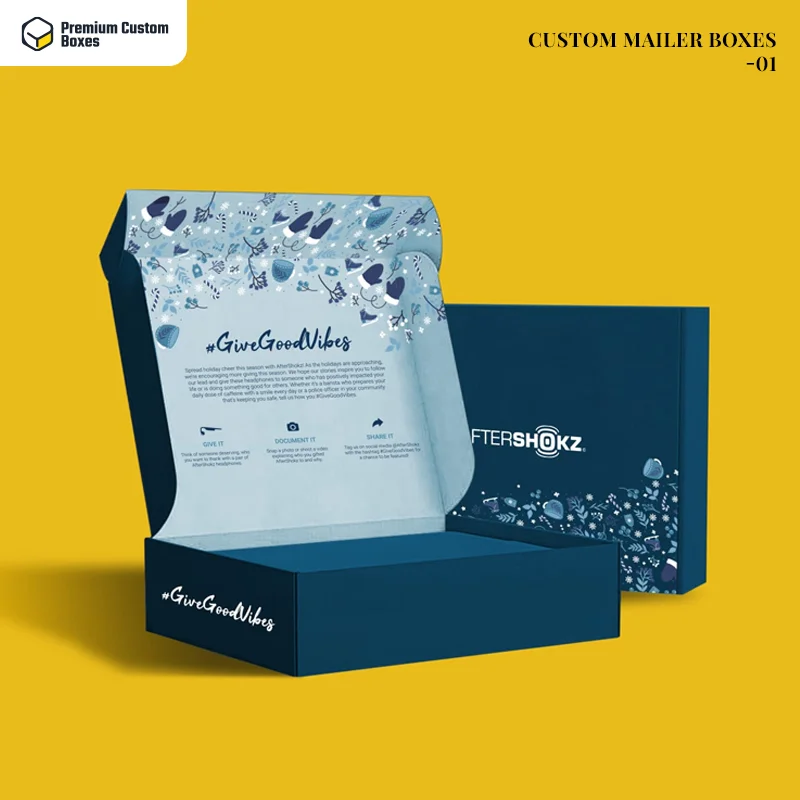

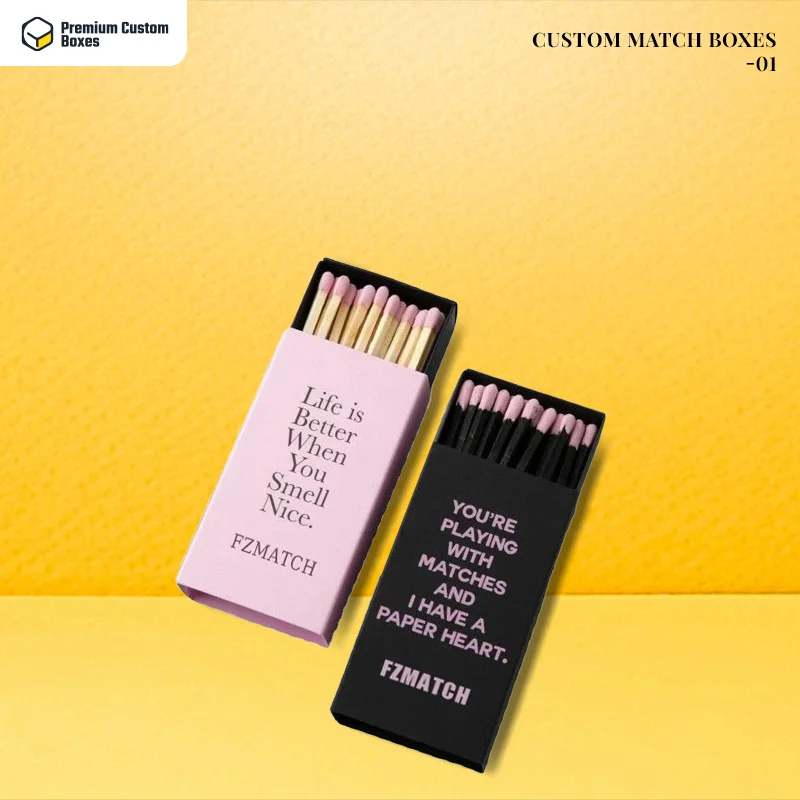

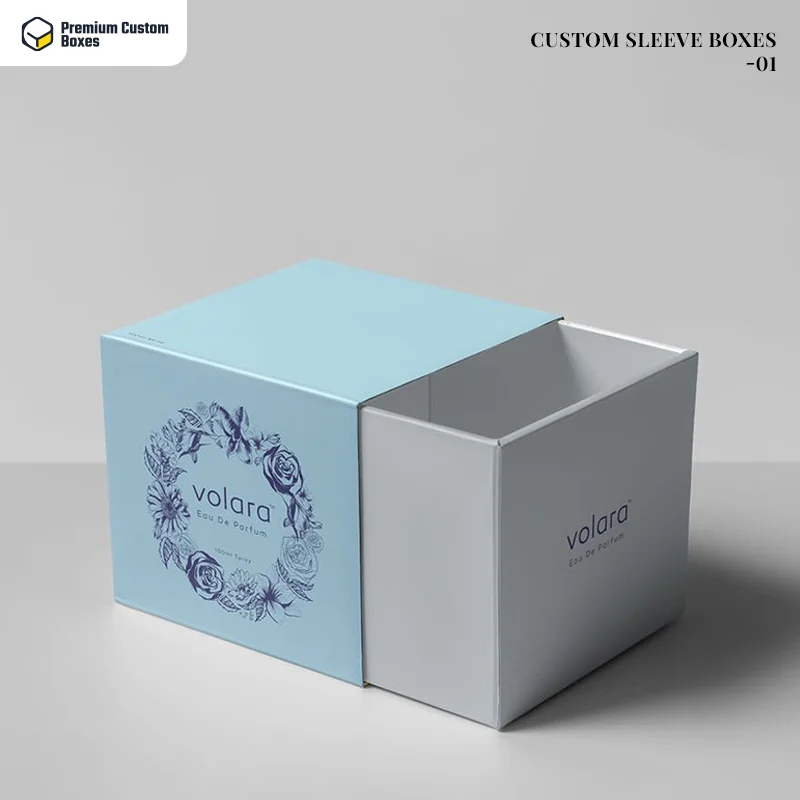

Related Products

Contact Our Customer Care Service

Are you looking forward to investing in our brand but have several concerns? Do you have ambiguity about our custom box services? If yes then you can contact our customer care representative and get all your queries answered in less than a day. Our diligent team is available for your service all around the clock. You can simply fill in the form on the website, email us on the provided email, or you can directly call us at the given number.

Get a Quote Call Us !

Latest Blogs

How Much Is a Pack of Cigarettes in Ontario in 2026?

Smokers and residents in Ontario search for answers to the question “How much does a pack of cigarettes cost?" Ontario...

READ MORE

The Power of Custom Gift Boxes for Valentine’s Day Branding

Many businesses now use smart strategies to stand out in a crowded market. If you want a perfect way to...

READ MORE

7 Best Valentine’s Day Gift Packaging Ideas for Your Loved Ones

Valentine’s Day is not just a couple’s day, but now friends as well celebrate this day to show their love...

READ MORE