The global market trend of Custom Wax Paper was valued at CAD 2580.2 million in 2024. But, the global demand for wax paper is predicted to surge at a CAGR of 4.8% and will reach CAD 4140.8 million by 2034. This high demand is due to the increased consumption of fast food. Food restaurants and brands are opting for customized wax sheets to preserve their food and to promote their business in the crowded markets.

If you are looking for wax sheets, then seek no further. Premium Custom Boxes manufacture customized wax paper using innovative packaging techniques. In addition to these, we provide all types of wax sheets to accommodate your business needs, from wet wax paper to dry paper. Our team uses food-grade coatings to make your sheets grease, water, or moisture resistant. Go through our services below and pick the best-fitted options for your culinary business.

Why Custom Wax Paper Is The Right Choice?

Wax paper is resistant to moisture. This paper is commonly used to wrap food items and prevent them from adhering to the surface. It also helps in maintaining the freshness of food. But, wax paper is not stable to heat, so avoid using it at high temperatures. This is commonly used to wrap the following food items:

- Burgers

- sandwiches

- Cookies

- Candies

- Frozen foods

Diverse Wax Sheets

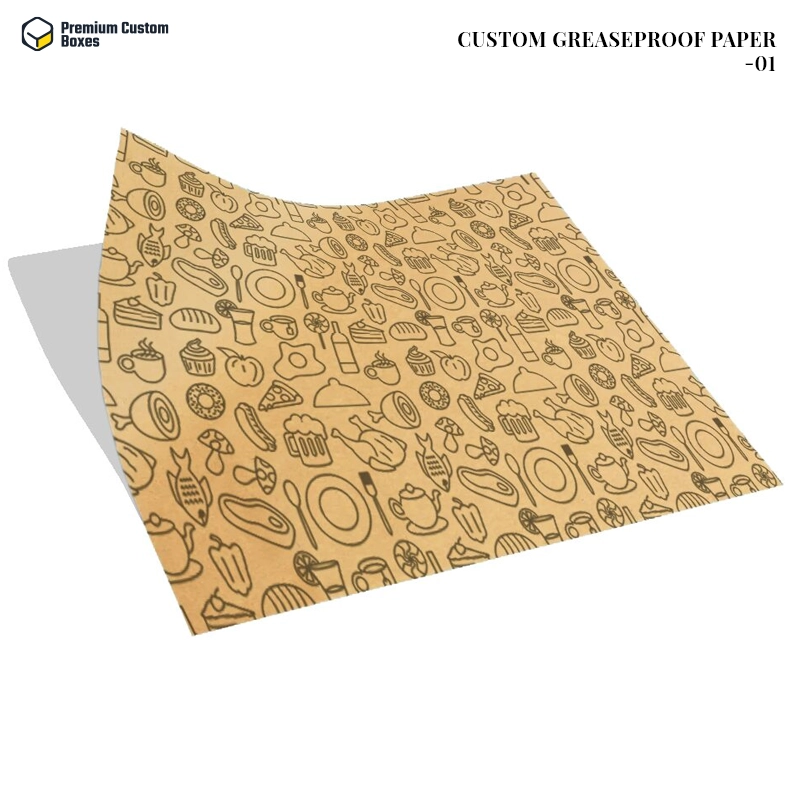

Our company offers different types of wax sheets to meet your product requirements. They are manufactured according to the nature of your product. They differ due to wax application methods for moisture and grease resistance. We offer the following types of custom wax paper sheets.

Wet Wax Paper

This paper has a coating on both sides and creates a smooth surface with a glossy touch. Wet wax sheets are widely known for their high gloss finish and excellent moisture resistance. These features make it suitable for preserving food items. They are commonly used for wrapping meat and other refrigerated or frozen foods.

Dry Wax Paper

Dry wax paper contains wax incorporated into the paper. It creates an oil repellent surface that resists moisture. These sheets are breathable. They also allow for some air exchange and moisture resistance.

Dry wax sheets are used for wrapping food items, especially hot or greasy items. They are also used for lining boxes or trays and general-purpose food wrapping.

Purpose Of Wax Wrapping Paper

Wax paper sheets are specifically used for moisture and grease resistance. These properties make them ideal for food packaging and many other household purposes. The wrapping sheets consist of the following features:

Food Packaging

- The paraffin coating on the wax sheet makes it resistant to water and other elements. The coatings make the custom wax paper for restaurants perfect for wrapping different food items.

- These sheets are also used for direct contact with food items to prevent them from drying out. They maintain the freshness and texture of foods.

- The wax paper wraps are also used to protect the processed foods and cereals.

Household Uses

- Wax sheet rolls are used for craft purposes.

- The non-stick surface helps line trays and is even used for other household chores, like the protection of furniture.

- The wax paper sheets help to clean windows.

- The wax paper rolls protect delicate items like jewelry or ornaments from damage.

- It is not a good heat heat-resistant as compared to parchment paper, but it is suitable for lower temperatures in lining baking trays.

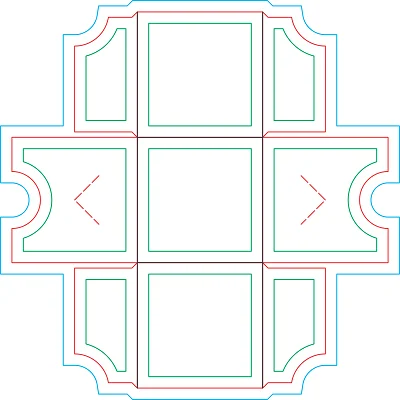

Production Of Custom Paper

The manufacturing process of wax paper sheets for restaurants undergoes various steps. Our team carefully produces perfect wax sheets to give you a stress-free experience. We prepare the wax sheets in the following way:

Base Preparation: A thin and low-weight sheet is prepared using a machine that produces large rolls.

Melting of Wax: The paraffin wax is heated in large heat-safe vessels and reaches a temperature of around 120 degrees.

Wax Applying: The wax is applied to the paper using two different methods, namely, roll coating, in which a roller applies a thin and even layer of wax to the flat surface of the paper.

The other one is dipping, in which the paper sheets are dipped into the tub of melted wax, and the excess wax is removed by allowing it to drip or by pressing.

Drying & Cooling process: The paper is passed through cooling chambers that harden the wax to firmly bond to the paper.

Sheets Cutting: The large rolls of wax paper are then cut into desired sizes and shapes.

High-Tech Customization Options

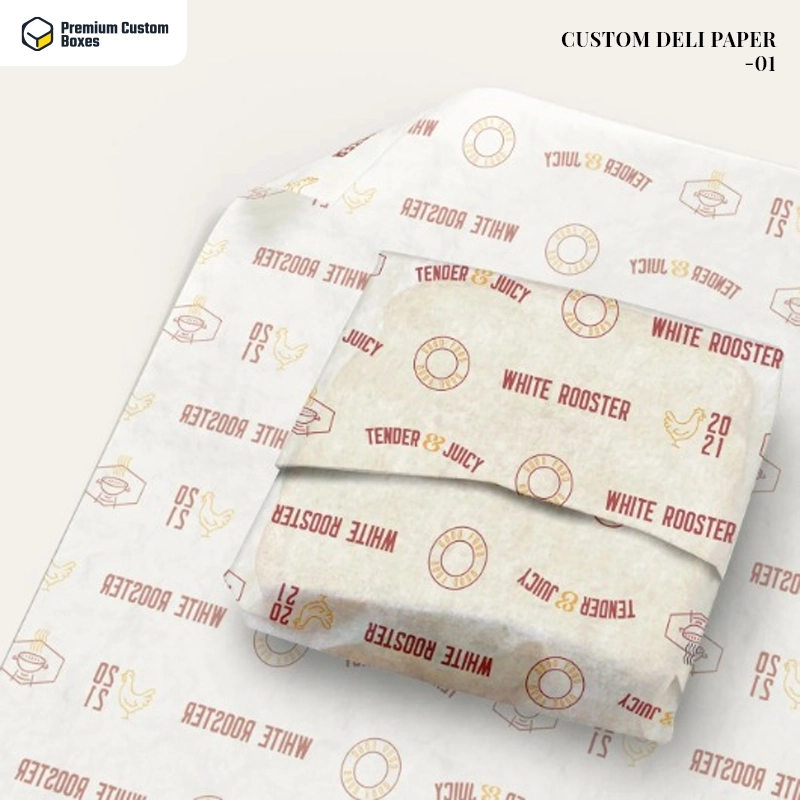

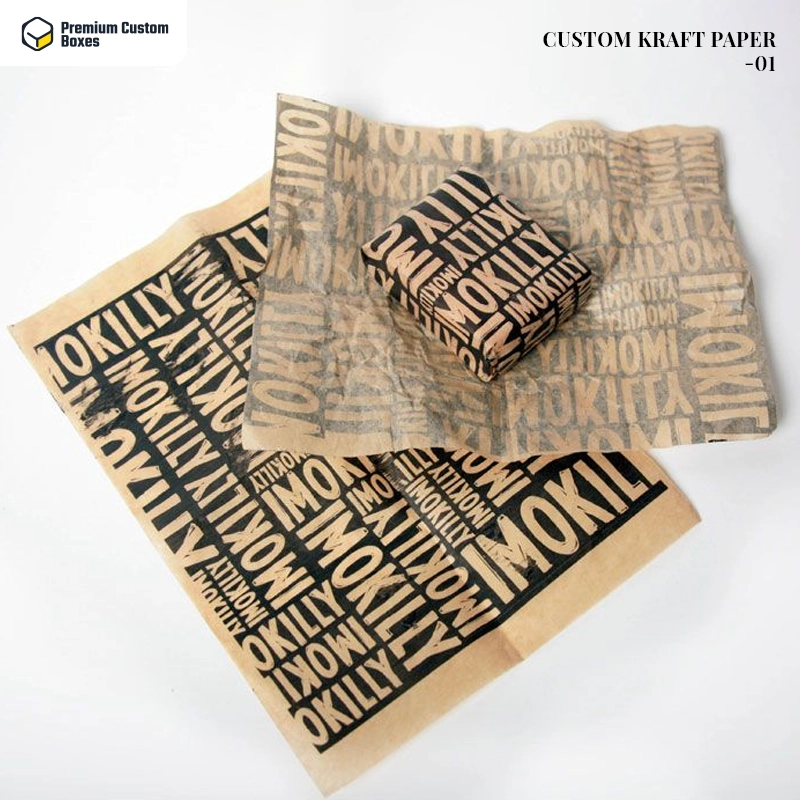

Our company offers different customization services for custom food paper to help you get recognition in the competitive markets. You can get your desired customized sheets at the most cost-effective rates. Our services include the following:

Quality food Grade Material

We use FSC-approved materials that are obtained from wood pulp. All of them are biodegradable. We use Kraft paper to produce wax sheets. The Kraft sheets undergo various chemical and mechanical treatments that make them non-stick and moisture resistant. Our company provides quality sheets that keep your food items fresh. They increase the shelf life of your products and prevent them from becoming soggy or stale. These materials not only help in making customized paper sheets, but you can also get custom wax paper bags to elegantly present your food items. You can get customized bags with your brand logos and colors.

Multiple Size options

Our manufacturing team provides different-sized options for custom wax paper for food to meet your product needs. Plus, our services are not limited; you can also request custom size options by contacting our team. However, our standard size options include the following:

Wax Roll Sizes:

- Common Roll: 15.24 m x 30.4 cm (50 ft x 12 in)

Wax Sheet Sizes:

- Common Size Options: 10″ x 10″, 12″ x 12″, 14″ x 14″, 15″ x 15″

- Standard Size options: 12″ x 18″, 15″ x 18″, 15″ x 24″

- Larger Wax Sheets: Some sheets can be up to 17″ x 23″

Printing Techniques

Printings are essential from various aspects. They not only add a professional touch but also make your products trustworthy. This helps in increasing your brand perception and sales. However, printing on wax sheets is a bit difficult due to the non-porous surface. This kind of surface causes the inks to repel. But our company offers some of the best printing methods for custom wax paper for food with nature-friendly inks. Given are our mechanisms:

Flexographic Printing: This is one of the best and affordable methods for printing on wax paper. In this process, fast-drying and food-safe inks are used. These inks are produced to stick to the surface of wax sheets. Flexography is perfect for prolific printing and is used to print logos or other brand elements.

Gravure Printing: It is used to get quality and precise print results. In this process, cylinders transfer ink onto the surface of the paper and produce sharp designs. However, this is a bit more expensive than flexography.

Printings to Avoid: We ensure to provide quality customized wrapping sheets and avoid any technique that can affect the quality of your products. We carefully avoid inkjet and laser printing onto the wax sheets, as they can cause the wax paper to melt or the ink to smudge.

Food Safe Coating Options

We offer different coating options for printed wax papers wholesale with specific properties. All of them are safe when they come in direct contact with the food items. So, you can wrap or pack your products without any worries. They prevent any outer elements from damaging the paper. Our popular choices include the following:

- Paraffin wax

- Soy wax

- Beeswax

These coatings consist of the following features:

- Non-Toxic

- Biodegradable

- Moisture Resistance

- Nature Friendly

Dos and Don’ts

Wax sheets excellently resist moisture. This property makes them perfect for wrapping food items that need protection from grease or moisture. However, some necessary precautions must be taken while using the customized wax sheets. They include:

- Wax sheets are not suitable for oven use. The wax can melt at high temperatures and thus cause smoke or other damage to the food. However, you can use parchment paper at high temperatures.

- Wax paper can be excellently used in the freezer, and it performs well in low temperatures as that to greaseproof paper. The wax coating keep sthe food items fresh and prevents freezer burns.

Our Evidence to Provide You with a Safe Custom Paper

Our company prefers the customer’s health and environmental safety. So, instead of just claiming, we have all the essential certifications proving our genuine customization services. Our company strictly follows the sustainability rules and has the following certifications:

- FDA: Food and Drug Administration Certification

- FSA: Food Standards Agency Certification

- ISO 22000: Food Safety Management System Certification

- FSC: Forest Stewardship Council Certification

- ECOSURE: Environmental Certification

Choose Us, Choose Quality!

PremiumCustomBoxes have helped countless brands in getting recognition in the competitive markets of Canada. So, make a mark by joining us. Mesmerize your audience by wrapping the food items in catchy custom wax paper sheets. Call us now to place your order and get our no-cost privileges:

- Free Delivery

- Fast Turnaround Times

- Free Design support

- No Hidden charges

- Wholesale & bulk order discounts

- 24/7 availability