No Die & Plate Charge

6 Days Turnaround

Free Shipping

FREE Custom Designing

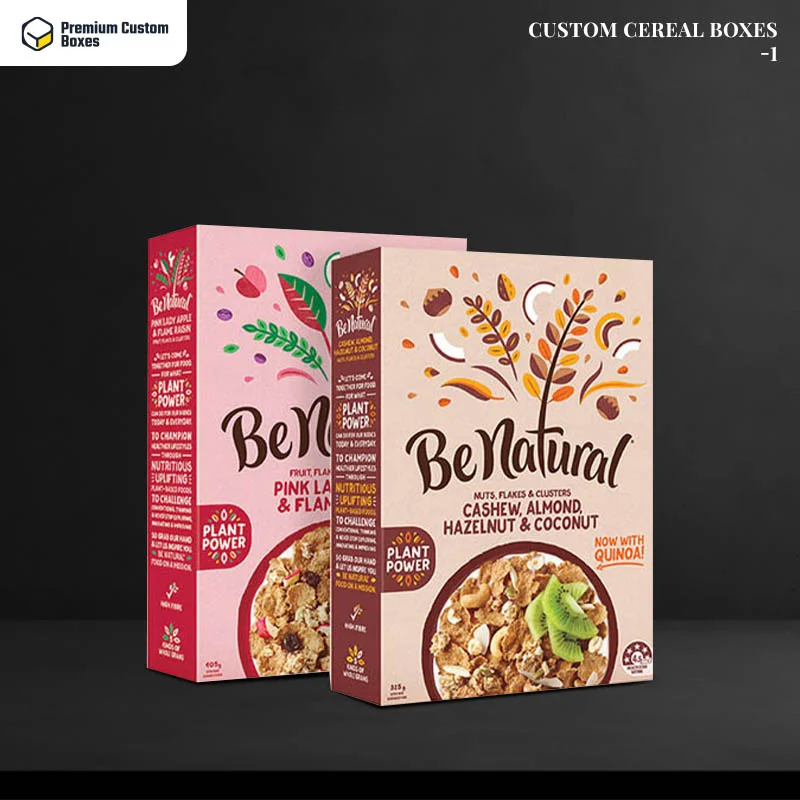

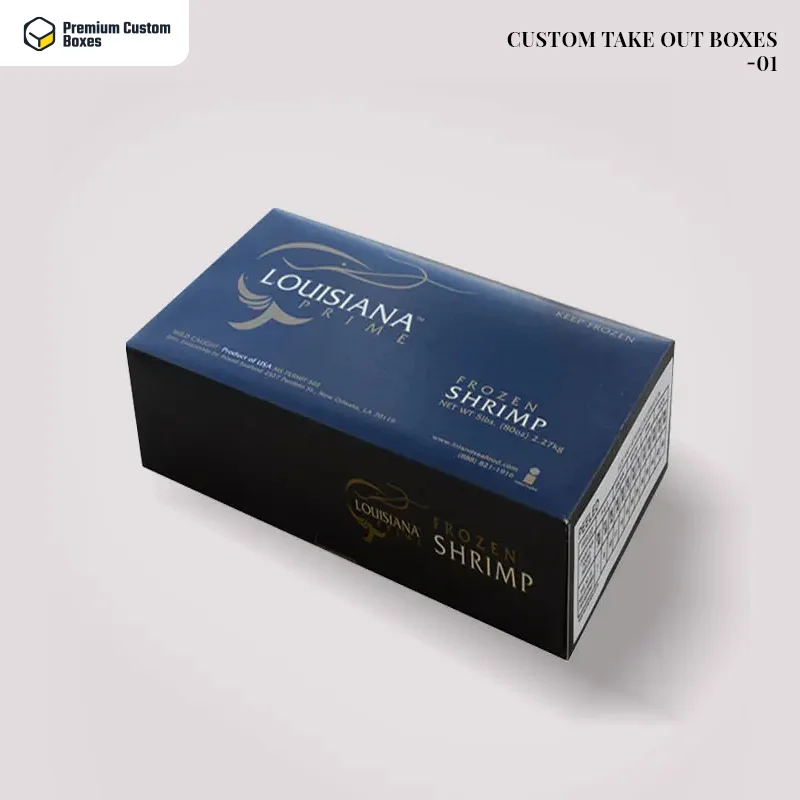

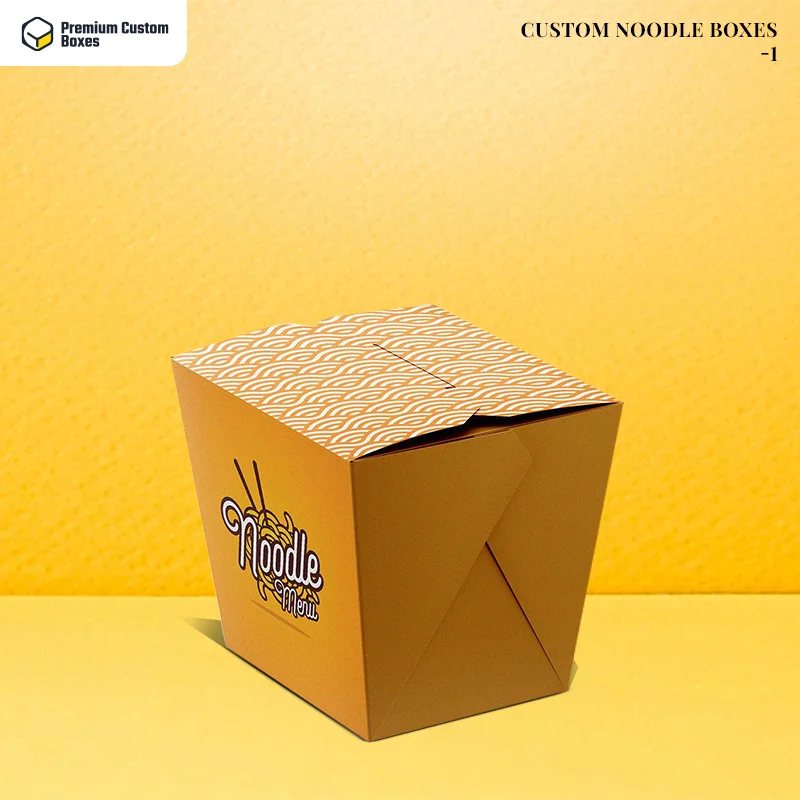

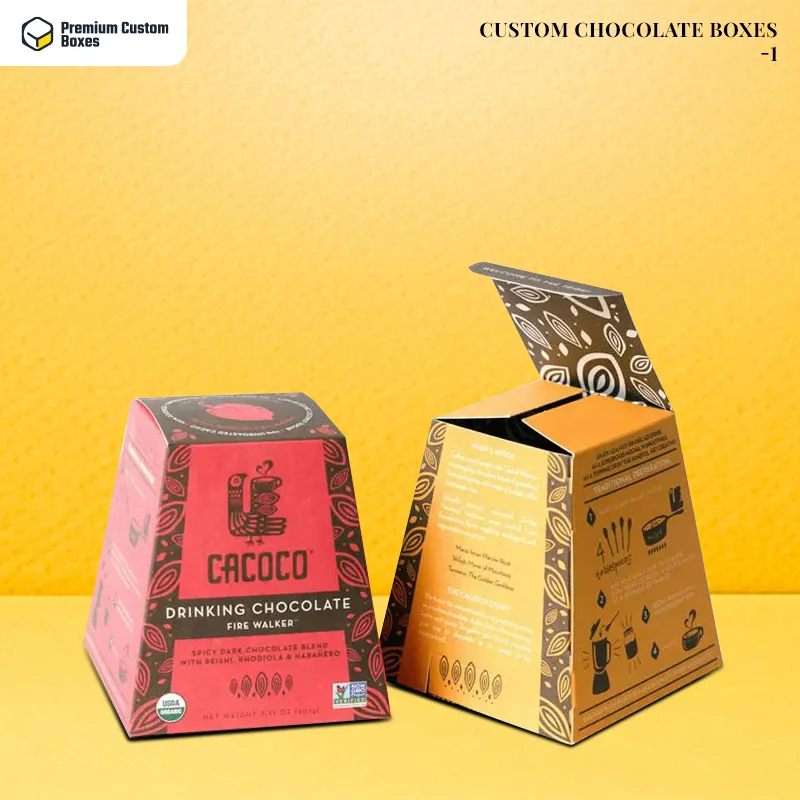

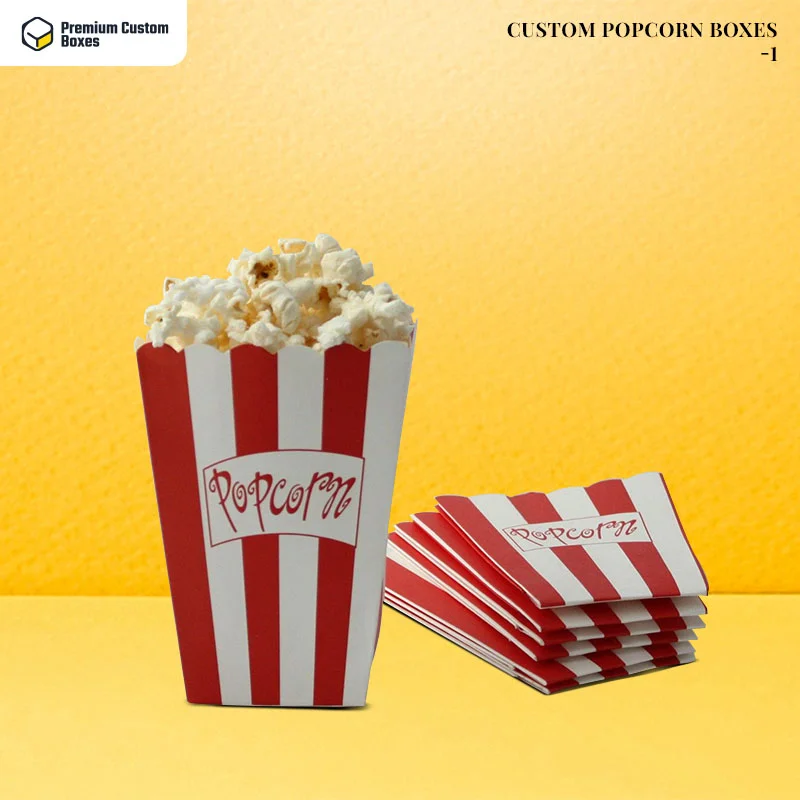

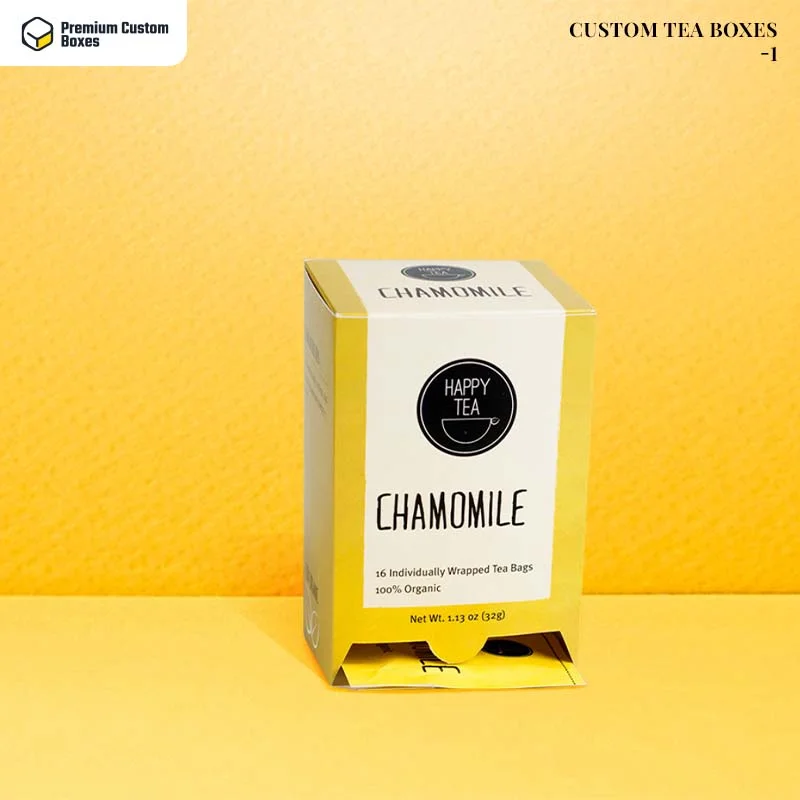

Custom Fast Food Boxes

Request Custom Quote

The fast food industry is gaining popularity with new items being introduced every now and then. The packaging demands increase with respect to industry growth as brands want to step ahead of competitors. No matter, if you are running a small food stall or a large fast food restaurant with versatile food options, custom fast food boxes are the optimal solution for catering to different sizes, styles and designs. So, if you want to market your brand effectively without spending much then explore our different customization options below and deal with your quality concerns.

Sustainable Material Solutions

Sustainable packaging is growing because people are switching their lifestyles to eco-friendly practices and are more likely to support brands with sustainable manufacturing processes. Material is the first step to take when making your packaging decision and for this, choosing recyclable ones not only helps you reduce packaging costs but makes a quick good value in the eyes of customers.

paper fast food packaging is not only lightweight but strong enough to give maximum protection during delivery. Different thickness options are available so you can get the most suitable packaging according to the weight of your food item. Kraft paper, cardboard, and corrugation are some most commonly picked materials because all of them offer maximum flexibility and customization.

Groundbreaking Design Elements

We all know that first impressions set the tone, no matter in which industry you are operating. In the fast-food industry, it is your packaging that will do the marketing of your brand. Custom Food boxes with attractive design elements and brand-related information are more likely to entice customers.

Consider having unique typos, designs, fonts and colours that match the theme of your brand. Also, stay updated with industry trends and you don’t need to hire a separate designer as we offer free design assistance. Here is how we ensure the quality of custom printed fast food boxes with each step contributing to a pleasant appearance:

Pre-Printing Process

In the first step, our expert designer creates artwork considering your brand marketing and branding elements. You can have a detailed design meeting with our team and then the final file format is prepared for print.

Printing Processes

We offer traditional digital printing processes so you can choose what suits best to your budget and quantity of the fast food boxes. The printing process is given below:

- Offset Printing is a traditional method suitable for large quantities and producing high-quality images.

- Digital Printing is a digital method suitable for small quantities and is a cost-effective printing solution.

- Flexography produces eye-catching visuals on take out boxes using flexible plates and is suitable for fast production

- Screen Printing gives a textured finish using a stencil called screen and produces durable results

Printing Techniques

As printing enhances your brand visibility, it is necessary to choose the right printing technique that produces an ever-lasting fast food packaging design. We have multifaceted techniques that remain vibrant for years:

CMYK

This printing technique uses four colour bases including cyan, magenta, yellow and black to produce versatile shades. This method gives a broad range of colours to choose from.

Spot Varnish

By incorporating spot varnish you can highlight fast food boxes with logo. Here spot means that you can add shine to specific spots in your pacakging boxes to lighten them.

Printing Finishings

After implementing the selected printing techniques, we ensure quality by post-processing that enhances the incorporated designs on your burger boxes. This is how we continue to maintain the quality standards:

- Different cutting techniques are incorporated to make desired shapes and cuts.

- Custom boxes are then folded using adhesives or automated folding.

- The whole box is then inspected to ensure quality control.

Laminated Food Boxes

Lamination enhances printing and gives maximum durability to custom fast food packaging. Laminated boxes are easier to clean as they provide a smooth surface. Also, we give different lamination thickness options including:

- Standard: 10-15 microns

- Premium: 20-30 microns

- Heavy duty: 40-50 microns

If you want polished and professional-looking food packaging then you can choose from the following options:

Gloss Lamination

Gloss lamination gives a high-gloss finish while protecting your French fries boxes against moisture and scratches. You can customize the lamination film for various thickness options.

Matte Lamination

Matte lamination gives a classy and non-reflective finish to personalised fast food packaging. This technique reduces glare and is an optimal choice for brands looking for sophisticated packaging.

Soft Touch Lamination

If you want fingerprint resistance then quickly opt for soft touch lamination. This lamination creates a moisture barrier just like the above two and also gives a velvet appearance.

Why Do Brands Choose Us?

PremiumCustomBoxes is chosen by professionals because we offer convenience, affordability and quality combined. We are fast food boxes wholesale manufacturers with years of experience in the industry. Our packaging always guarantees to give the brand the renowned place in the market it deserves.

International Standard Shipment

You don’t have to wait long when making an order with us. We give the fastest turnaround following the custom regulations. However, if you want a rush order, we can surely make that happen too.

Non-Stop Customer Service

You can contact our 24/7 customer service at any time or from any region to deal with your queries. An email and phone number are mentioned, although you can also live chat with us.

No Hidden Charges

We ensure transparent payment procedures with our customers with all costs being discussed before the start of manufacturing. Nothing changes in between and you will have to pay as clearly communicated with us.

Free Quotation

Avail of a free quote from our website where you can fill out all necessary information related to fast food boxes packaging. A message box is available if you want any more specifications like themed packaging.

Make A Deal Now!

If you want to become the top priority of foodies then protective and attractive packaging can make a huge difference. You are never too late to have your dream packaging. Just make an ideal deal with us and get recyclable fast food packaging without pinching your pockets.

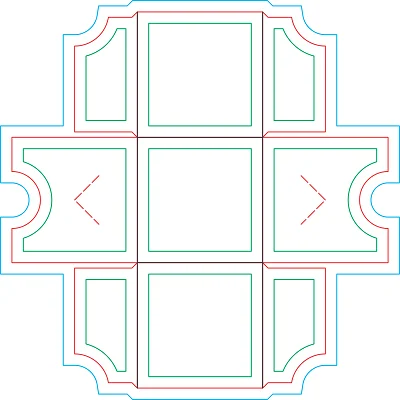

Artwork Preparation Guide

Preparing artwork for various purposes, whether it's for print, digital media, or other applications, requires attention to detail and adherence to specific guidelines. Here is a general artwork preparation guide that you can follow:

Cutting Line (Red Lines):

Indicates the cut at its final size.Important artwork and text should be placed at least 0.125 inches inside of the cutting line.

Bleed Area (Blue Lines)

Indicates where the bleed line is located. Any artwork which goes to the cutting line should be extended to the bleed line to get a seamless print.

Safe Area (Green Lines):

Indicates where artwork and text should safely be placed inside. As a industry standard, all artwork should at least be placed 0.125 inches away from the cutting lines unless your design in intentional.

Perforation Lines (Red Lines)

Perforation line refers to paper that is punched with very small holes to allow the paper to be torn and folded easily.

Creasing Line (Black Lines)

Indicated where the product is to be folded.

01

Choose Your Box

Start by browsing our extensive range of box styles and designs. Whether you're in the market for something simple and classic or intricate and bespoke, we've got a multitude of options to suit your needs.

02

Customize the Design

Once you've chosen a box style, it's time to make it uniquely yours. Upload your design or collaborate with our in-house design team to craft a packaging solution that resonates with your brand's aesthetic and vision.

03

Select Materials and Finishes

Our platform allows you to pick from a variety of materials, be it eco-friendly options, premium finishes, or durable structures. Enhance the tactile experience with finishes like matte, gloss, embossing, or specialty textures.

04

Review and Approve

Before we move to production, we'll send you a digital proof or a physical sample upon request. This ensures you're 100% satisfied with the design and materials chosen. Review, make any necessary changes, and give us the green light when you're ready.

05

Production Begins

Once you've approved the design, our team gets to work. With state-of-the-art machinery and a dedicated workforce, we ensure that each box is crafted to perfection, adhering to the highest quality standards.

06

Shipment and Delivery

With our efficient logistics network, we guarantee timely deliveries. As your boxes are packed and prepared for shipment, we'll provide tracking details to keep you informed every step of the way. Sit back and wait for your premium packaging to arrive at your doorstep.

Cardboard

Corrugated

Kraft

Rigid

Anti Scratch Lamination

Aqueous Coating

Lamination

Silk Lamination Cards

Soft Touch Coating

Spot UV

Gloss Lamination

Gloss Varnish

Matt Lamination

Matt Varnish

Debossing

Embossing

Foil stamping

Window Patching

Customer Reviews

Reviews

Great company to work with... my boxes arrived safely.

Excellent product quality and fast delivery. Highly recommended!

Good value for money. The product meets all my expectations.

Related Products

Contact Our Customer Care Service

Are you looking forward to investing in our brand but have several concerns? Do you have ambiguity about our custom box services? If yes then you can contact our customer care representative and get all your queries answered in less than a day. Our diligent team is available for your service all around the clock. You can simply fill in the form on the website, email us on the provided email, or you can directly call us at the given number.

Get a Quote Call Us !

Latest Blogs

Celebrate Christmas With Meaningful Gifts And Beautiful Boxes

Christmas brings joy and opportunity to enjoy life outside of the busy and repetitive routines. This gives busy families an...

READ MORE

How Custom Boxes Can Be Smart Packaging Solutions

Operating a business today involves wearing many hats simultaneously. From running the business and promoting it to satisfying the customers,...

READ MORE

How to Choose the Right Pizza Box Size in 2025?

Can you imagine your shop losing customers because they thought your pizza box size was too much to handle? Well,...

READ MORE