In this high-tech era, every industry is growing progressively. Every brand is competing high to create a notable difference with its products. However, what makes them dominant is quality packaging. Every brand spends thousands of dollars on exquisite packaging. But, often the packaging costs get so high that the brands don’t even get the desired profit.

Considering the growing demand for packaging, it is necessary to research thoroughly and find proven solutions that can help reduce packaging costs without compromising the quality. If you are hunting for innovative packaging approaches that can give you maximum profit and brand perception while reducing packaging costs, then keep scrolling down because we have discussed some of the trendsetting approaches that help in reducing the cost of a product’s packaging and can lead to higher profits. But first, let us inform you of the reasons that cost you high dollars and fewer profits because of packaging.

What Factors Can Raise The Cost Of Packaging?

Packaging is not about materials. It involves various factors that drive up the overall costs and businesses end up with zero profits. If you are in the same boat and unable to identify the real causes behind your high packaging costs then here is the answer to your confusion.

- High shipping costs.

- Poor packaging lines

- Unoptimized Packaging

- Overly designed Packaging

- Spending on box dimensions instead of product dimensions.

10 Groundbreaking Approaches to Reduce Your Packaging Costs

With up-to-date ideas, now you can gain high profits and reduce your overall packaging costs. But don’t worry, you can do all this without risking the quality and aesthetics of your products. Simply adopt the following approaches to design custom boxes from scratch to end and let your brand shine without spending a fortune.

1. Opt for Green Packaging Materials

Packaging materials are essential and they can be the reason for high or low costs. We all are well aware of the variety of materials available in the market. From plastics to styrofoam, glass or polythene bags, and paper-based materials, various brands use expensive materials for their products.

The paper-based packaging materials such as kraft, corrugation, rigid, buxboard, or cardboard are widely used for sustainable packaging and they excellently help in saving costs. They are budget-friendly and do not cost extra dollars. Also, paper-based materials attract eco-minded customers because they can be recycled and are FSC-approved.

2. Minimal Design Approach

Minimal design approaches play a key role in reducing the overall packaging costs. A messy or confusing design on the packaging box keeps the customers away. However, a clear and precise design approach can make the product eye-grabbing. Less design means less usage of resources. You can choose a less expensive colour approach. CMYK and PMS are both print-color models. But CMYK is a more economical technique as compared to the Pantone matching system. You can reduce the packaging costs by opting for less expensive printings. This can ultimately lessen the die cutting costs.

3. Use Add Ons, If Necessary

Various brands prefer to use additional decorative elements to enhance the product appeal but add-ons are not mandatory elements. Only luxury brands or high-end products need them to increase product presentation and protection. But for ordinary products or food packaging, add-ons are not necessary.

They include inserts, dividers, handles, embossing, debossing, and foil stamping. You can use only the most vital add-ons depending on the products and reduce the packaging costs. Because for these additions, you have to pay extra bucks.

4. Hire Qualified Trained Staff

Qualified employees are the backbone of every industry. So, by Hiring trained staff you can reduce packaging costs by improving efficiency and minimizing errors. Qualified workers can pack products accurately thus, reducing the risk of product damage, which can result in costly returns or replacements.

Trained employees are more proficient at optimizing packaging material usage and reducing waste. They can also handle packaging machinery more effectively, reducing downtime and maintenance costs.

5. Use Custom Size Packaging

Oversized packaging always ends up messing up your product and driving up shipping costs. So, custom-size packaging helps to snugly fit your products. This also lessens the material usage and ensures secure packaging for your products. Choosing the right packaging size by accurately measuring the box dimensions, will not only cut costs but also help in faster and smoother shipping.

Another strategy to save costs is by using small packaging boxes, as they need fewer raw materials, lowering material costs per unit. Additionally, they take up less space during shipping, allowing more units per shipment and thus cutting down on shipping expenses. So, if you are still thinking which packaging should the company use to minimize cost? Then, custom packaging is the only solution for all your worries.

6. Automate Your Packaging Process

Automation of packaging might sound expensive. However, it is the best solution for cutting various costs in the long term. Moreover, manual packaging is time-consuming and needs more employees which can ultimately increase the packaging costs.

By automating the packaging process, you can ensure consistency, reduce material waste, and get higher output at faster rates. In addition, using the advanced packaging trends alongside automating processes can save costs and help you create notable differences in your sales.

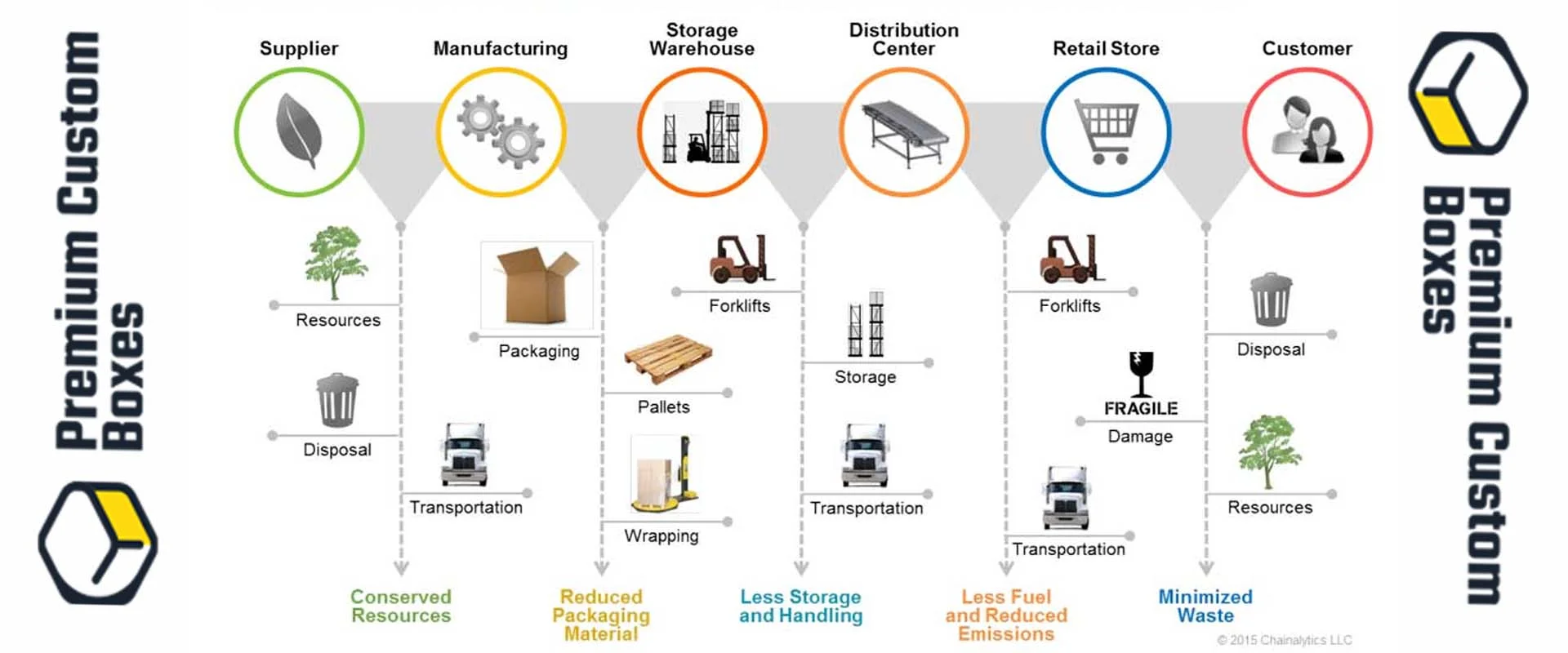

7. Build Long Term Partnerships by Negotiating with Suppliers

By building a strong relationship with the suppliers, you can get higher profits. The packaging companies provide various discounts to their loyal customers. The wholesale and bulk purchases can help in reducing many costs. You can sign a long-term contract with trustworthy suppliers and this way you can lower the prices of packaging materials and other customization services.

8. Use Lightweight Materials

Lightweight materials offer great benefits. They can help in reducing shipping costs. So, instead of using heavy-weight materials, you can shift to lightweight kraft, thick corrugated, or cardboard materials. They are not only lightweight but also lower production costs when purchased in bulk. An example of a company connecting with customers to add value to its package redesign strategy is McDonald’s. They redesigned the packaging strategy by aligning it with sustainable and lightweight paper-based materials. So, choosing the right packaging material for custom boxes can help you reduce costs.

9. Buy In Bulk

Buying in bulk can greatly help in saving costs. Packaging suppliers offer bulk order discounts and this reduces the costs per unit. Not only this but buying in bulk can help in reducing shipping costs. The greatest benefit is that you can save yourself from the sudden price hikes or disruptions caused in the markets. So, provide the right packaging dieline for your bulk order to get your desired packaging.

10. Multi-Purpose Packaging

Packaging can be designed to serve multiple functions. You can use the standardized packaging for more than one type of product. This reduces the need for different types and sizes of packaging boxes. By doing this, you can reduce the production, material, and storage costs.

For instance, for fragile and non-fragile products, you can use a single box by incorporating inserts or dividers for the fragile items. Multi-purpose packaging also provides flexibility in scaling operations and optimizing storage, making it both cost-effective and resource-efficient.

Enjoy Quality Packaging By Saving Costs with us!

By now, you must be aware of the trailblazing strategies that can help you get maximum profits without spending extra dollars. Saving costs does not mean that you have to jeopardize the quality of your products, it means to act smartly to stand against the competitors in this fast era. We have discussed all the necessary ideas that you must opt for your brand.

From sustainable materials to customized size and dimensions, and from automating the manufacturing process to hiring qualified staff, redesign your strategy and enjoy the best of the perks of having these innovative solutions. However, if you still feel any confusion regarding costs or customized packaging then relax because PremiumCustomBoxes has expert staff and years of packaging experience. You can avail the non-stop customer services for any queries.