Custom boxes have been becoming a crucial part of the retail sector. Even most online stores prefer customized packaging as it helps them connect with the customers and give personalized protection to the packed items.

Brands prefer printed boxes over general packaging because they want to outshine their competitors. Moreover, investing in printed boxes helps brands to get a tool to promote themselves. In Canada, thousands of brands, both local as well as foreign, are in intense competition with each other.

To decorate custom box packaging in Canada companies provide advanced printing methods and help you combat competition. To understand how custom packaging is printed in Canada, let’s read the blog.

Importance Of Printing

Packaging is an important factor that defines a brand’s failure or success. With time as the demand for products is increasing globally so does the supply. No doubt this balance in demand and supply makes day-to-day products accessible to people around the world however it is creating tough competition among the brands.

Brands must understand the competition so that they can realize the importance of custom packaging. From giving you distinction to helping you promote your brands and getting the attention of customers, printing on the boxes plays a significant role. Customers depend heavily on the presentation of your practice and packaging is a crucial factor in product presentation.

Steps Involved In The Printing Of Custom Boxes

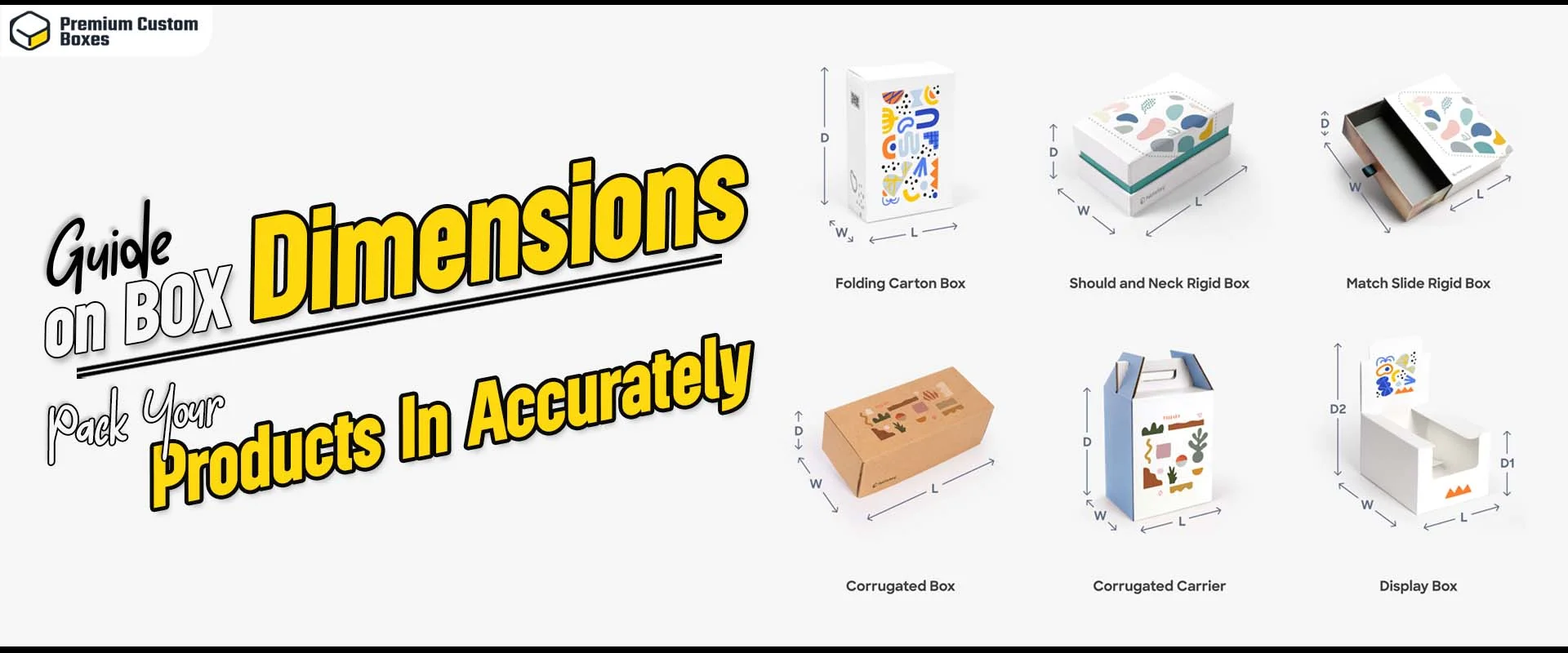

For custom boxes Canada, several steps are involved. It is crucial to perform each step in the right and chronological manner to avoid any kind of errors and to get a professional look at the boxes.

Design Preparation

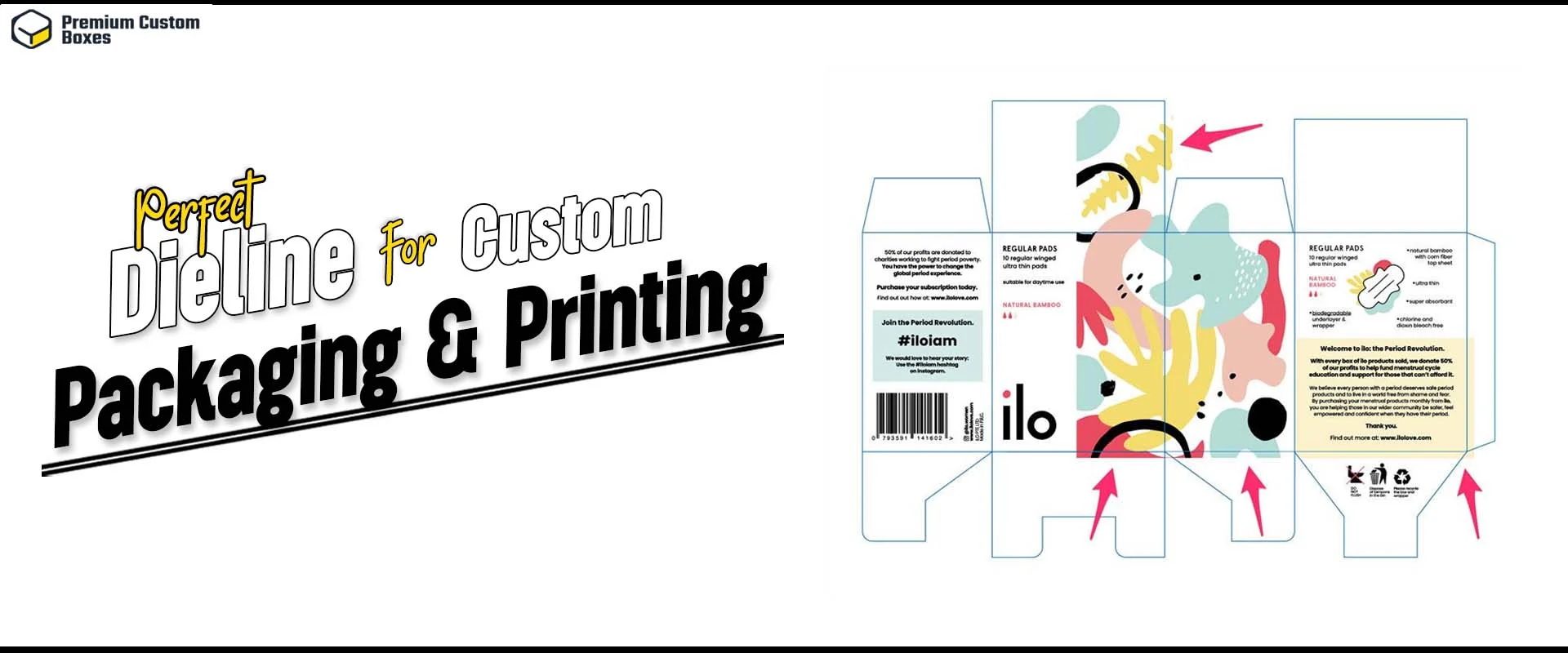

In the first step, one must have to create the main style, size, and design concept. A graphic designer creates artwork with the help of different software such as Adobe Illustrator and Photoshop. The main thing is that the boxes’ designs must resonate with your brand’s theme, product type, and relevant images. As we know promotion is the main concern of brands, therefore box manufacturers add logos and other branding elements at the time of custom box design making.

A good and professional box manufacturing company sends digital proof of the final look of the box. Even some brands like PremiumCustomBoxes, facilitate the customer by providing their Design Online Software using the customer themselves to decide the overall design of the box.

Plate Making

Some printing methods rely on the use of plates to print custom packaging designs. Flexography and offset printing methods involve the use of metal and photopolymer plates. However, digital and screen printing do not require any plates. As designs consist of different colors each plate represents one color. Digital printing involves the direct printing of design on the substrate and screen printing is based on the use of mesh for design creation.

Printing

There are multiple types of printing methods used in the custom boxes market. Customers or manufacturers select the printing method depending upon the complexity of design, material, and available time duration. The complexity of your design, the amount of boxes, and the material define which printing method is suitable. For the best result always choose the right packaging material and get the desired look of the box. The main four types used in:

Offset Printing

Using offset printing you can transfer the colour to the plates, then transfer the design to the rubber blanket and then to the substrate. This method not only gives a flawless design, but it is also perfect for intricate designs. Moreover, for bulk orders such as custom retail boxes, this method is a good choice as it gives consistent colour and design patterns.

Flexography

Flexography also gives quality design, the best for complicated artwork, vibrant colour patterns, etc. As flexible printing plates are used here that is why you can use this method on different surfaces. Like offset printing, bulk orders can be printed with this method.

Digital Printing

Customized packaging boxes can be printed for quick runs by digital printing methods. Small businesses need smaller orders at economical rates and digital printing is a suitable method in this regard as no printing plates are required. If you want to knwo more about custom boxes for small business you can read our guide at the PCB site.

Screen Printing

Screen printing comes under a manual process, here manufacturers have to use a mesh to transfer ink on the material. For bright colours screen printing can be a good option however it is only suitable for simple designs.

Colour Mixing Process Used In Box Printings

For different shades of colours, you have to select the relevant colour-mixing process. Designing on digital platforms of custom boxes wholesale RGB method is used, on the other hand for physical printing CMYK and PMS color mixing models are used. For printing different inks are available in the market. Brands can select an ink type by keeping in mind the printing methods, designs, and materials. The three common inks are:

- Water-based inks

- Soy-based ink

- Petroleum base ink

Colour mixing processes

CMYK is a subtractive method that uses primary colours, especially for full-colour printing on personalized boxes. In CMYK C stands for Cyan, M for Magenta, Y for Yellow, and Key for black(black). This works by subtracting various wavelengths of light to give the desired colour. Different concentrations of cyan, magenta, black, and yellow are mixed to create a wide range of shades. the role of black colour is to create the contrast of the shades by deepening the shadow. Boxes that are used by e-commerce businesses or as PR packages are printed with contrasting shades of the same colour and CMYK proves useful here.

RGB stands for red, green, and blue. This is used on digital displays and monitors. It is an additional colour-mixing model in which different varieties of red, green, and blue are added. Different combinations and intensities of these colours create a broad spectrum of colours and different shades. When all the colors are added then this method gives white color.

PMS is a standardized process and stands for Pantone matching system. PMS ensures colour consistency on custom box packaging. Each colour is assigned a unique Panton number that is standardized and pre-mixed. Here instead of adding and subtracting lights, pre-mix formulas of colours are used to print packaging.

Post Printing Processes

After the printing on the customized packaging boxes, we have to make sure that the printed design lasts for a long duration. Coating presents the designs from fading, scratching, and fingerprints. After printing, workers die cut, fold, crease, and glue the boxes. Sometimes customers want add-ons on the boxes for a premium look and to increase the perceived value of their product.

Drying And Curing

Depending on the type of ink and printed method used for custom boxes with logo, the sheets may need to dry. Water inks dries under air and UV printing cures the pigments under UV light. UV lamps throw light that solidifies the ink and makes sure that it remains adhered to the box.

Laminating And Add-ons

To ensure the protection of the boxes from moisture and to keep the design impeccable, you have to apply lamination or coatings on the package. Varnishes or aquos coatings are applied to create an appealing look specifically for custom printed retail boxes we have to create a shelf appeal. Laminations give a shiny look to the box surface. Some of the coatings that are available in the market are gloss, matte, UV, and silk screens.

You can add laminations are coatings to the boxes to get a luxurious and elegant look. These add-ons include embossing, debossing, foil stamping, metallic coating, holographic coating, etc

Die-Cutting and Creasing

Die cutting is a process which creates a template or blu print for the custom packaging. Die cuttings machines give a specific shape to the sheet. To cut the boxes die cutting machines have sharp metallic edges. To make sure that the final look of the box looks great and professional you can use creasing rules that will crease the material without cutting through the surface.

The printed sheets for personalized boxes are then fed into a die-cutting machine where the sheets are cut according to the creased lines. This method gives a box in a refined and accurate shape and in a flat form.

Folding and Gluing

Now the box manufacturer folds the box into the final shape. The crease lines make it easy to fold the box. Small box manufacturers can fold the boxes manually but at higher levels, professional folding machines become necessary to reduce time and increase efficiency.

Glue is applied on custom boxes Canada to maintain the box shape and style. For a strong bond between the material and the glue, companies have to press the parts of the boxes.

Quality Control

All the top-notch packaging manufacturers visually inspect the boxes to make sure that there are no printing errors, colour mistakes, or structural issues with the boxes. To make sure that the durability, weight-bearing capacity and other specifications of the boxes companies use different tactics. If an error appears, brands can rectify the issues before shipping.

Conclusion

Printing on custom boxes is an intertwined process and involves collaboration between multiple professionals such as designers, press technicians, printing professionals, etc. To get the percent boxes, all the processes must be done in a defined sequence. To get high-quality printings on the boxes you must have to use cutting printing facilities that can be acquired only by a high-end custom box manufacturer like PremiumCustomBoxes.ca.

Read More: Stand Out In Canada’s Retail Market With Custom Boxes