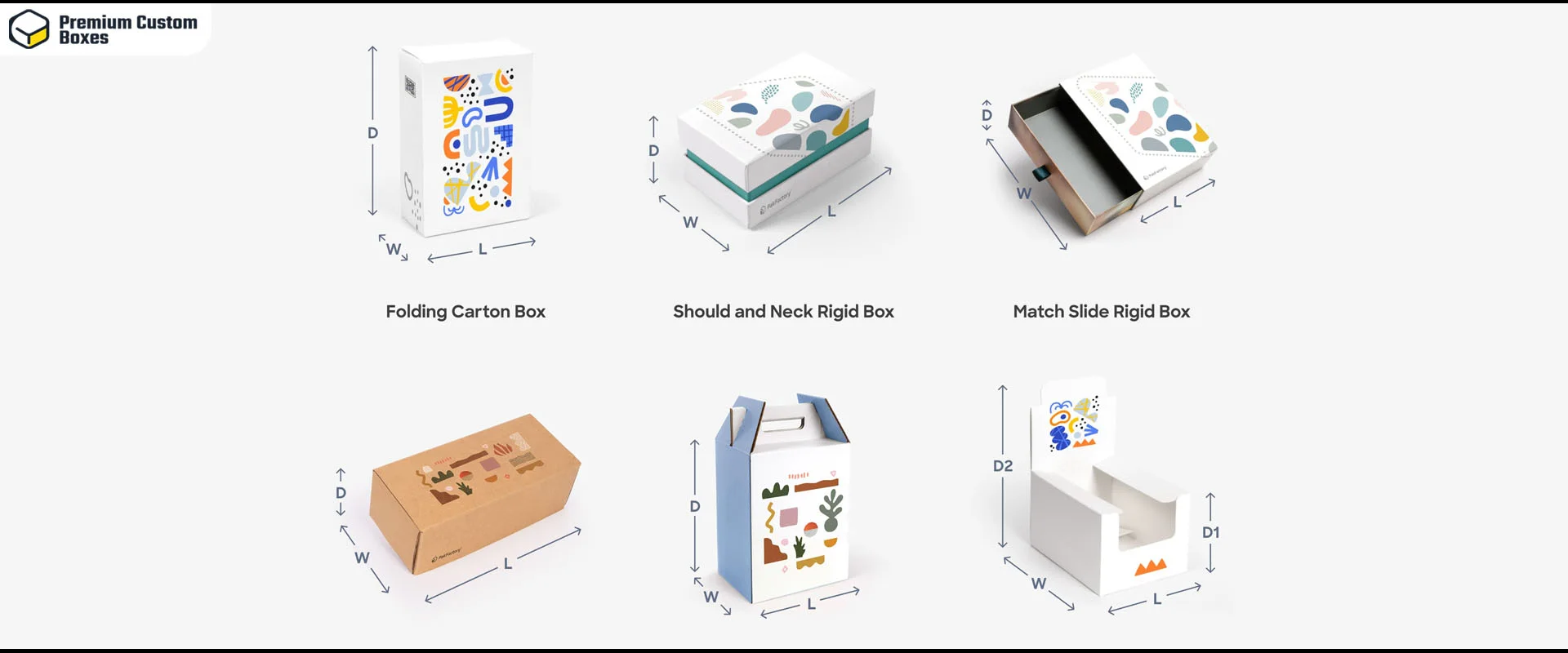

There are various box types, and their dimensions may be required for different reasons, including carrying capacity calculations, scaled packaging, storage, or household management. To avoid inaccuracy, it is essential to learn the order of taking measurements and the procedures required to take measurements. In this how-to guide, you will learn all there is to know about box dimensions, ordering a box, and measuring your box correctly.

Importance Of Box Dimensions

Box dimensions are typically expressed in length, width, and height. These dimensions determine the box’s dimensions and volume, which are very important when performing tasks such as pricing for shipment, packing, or selecting storage solutions. Some of the reasons for which box dimension measurement is essential are:

- Shipping and Packaging: The dimensions must be correct to avoid extra prices and ensure the space can be used efficiently.

- Storage and Organization: Proper measurements ensure boxes are correctly shaped and sized to fit the products best, reducing time and space consumed.

- Custom Box Design: Accurate measurements are needed to get boxes suitable for the different products brands must pack.

How To Measure A Box

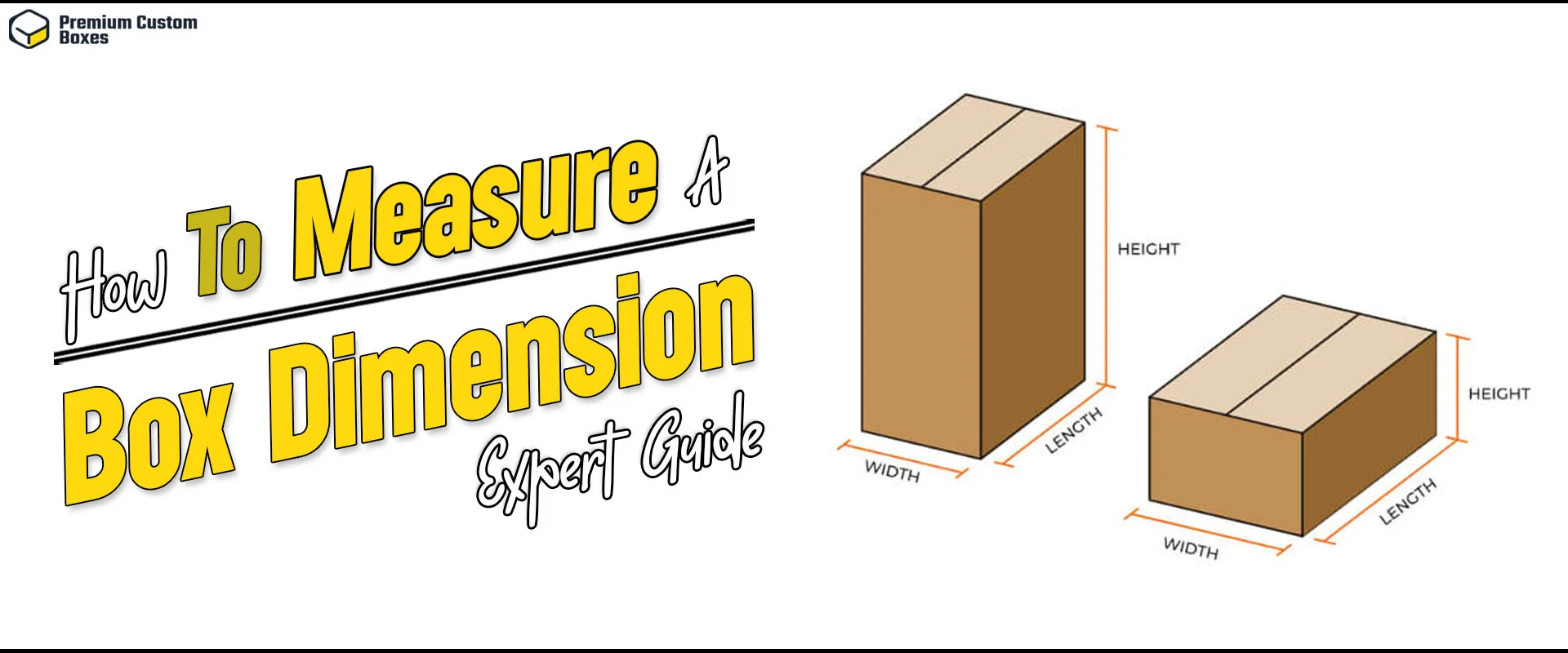

To measure the box, consider several dimensions to measure all the sides accurately. This is vital for accurate measurements. See below what are the different sides of the boxes:

- Length: The longest side of the box.

- Width: One of the sides of the box, when seen from above

- Height (or Depth): The height of the box is the distance between the box’s bottom and top surface.

This order is familiar in engineering and design, making it easy for businesses and industries to understand the best size of the boxes for their products. There is a systematic way of measuring a box. Here’s a detailed step-by-step guide:

Step 1: Gather Your Tools

You’ll need:

- A measuring tape or ruler

- A notebook and pen for measuring specifics of size

Step 2: Position the Box

It is recommended that the box be rested on a flat surface so that the opening of the box is on top of the four legs. This orientation helps to demarcate the areas when measuring is being done.

Step 3: Measure the Length

The length is the longest side of the box (when viewed in the plane from the top, as A-B in the figure below). Length is obtained by placing the end of a measuring tape or ruler on one edge of the box and pulling it to the other. Measure it in inches, centimetres, or whichever other unit you prefer.

Step 4: Measure the Width

The width is the narrow dimension of the box when viewed from the top, like an open-top box. Measure the width across the breadth from one end to the other and record this measurement.

Step 5: Measure the Height

The height (sometimes referred to as depth) is the height of the box perpendicular to the base. Lay the measuring instrument at the end of this box and take the measurement.

Step 6: Note The Box Dimensions Order

Always list the measurements in the standard order: length, width, and height. For instance, if the box has dimensions length, width, and height of 20 inches, 10 inches, and 15 inches, respectively, the length width height order will be written as 20” x 10” x 15” L x W x H.

Measuring Techniques For Accuracy

No one wants to get a box bigger than the product, as it shows a lack of professionalism. On the other hand, if a box is smaller than the size of the product, then it will be a complete waste. So, it is inevitable to perfectly measure a box dimension accurately. For this, you can use the below-mentioned points:

- Use the Right Tools: For measurements of large boxes, use a stretchable steel measuring tape; for small box measurements, a steel ruler will suffice.

- Double-Check Your Measurements: To avoid making mistakes when calculating the dimensions of each side of the door, you should measure it at least two times.

- Round Up for Shipping: When shipping, for better pricing, round up to the nearest numbers on the table to yield a more accurate cost.

- Include Padding: If you use the box to ship items within the box, include the space occupied by padding or filler.

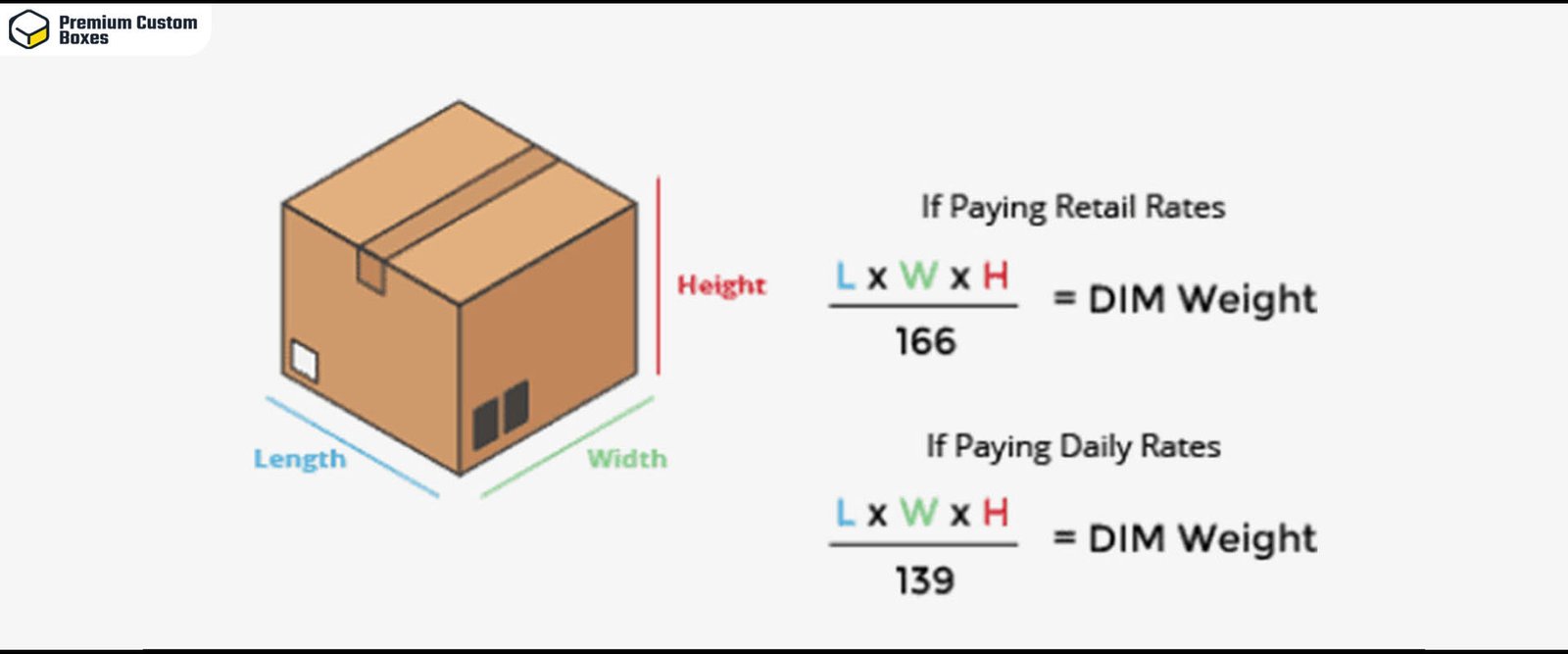

Dimensional Weight For Shipping

Many companies use the dimensional weight to charge the customer because its basis depends on the box size.

To calculate dimensional weight:

- Measurements in order of the box’s length, width, and height in inches.

- Take the total and divide it by the carrier’s dimensional factor, which for most domestic shipments is 139.

For example, if your box measures 20” x 10” x 15”:

Volume = 20/3 x=x 10/3 x=x 15/3 = 3,000/3 = 3,000 cubic inches

Dimensional Weight = 3 000/139 ≈ 21.58 lbs

Here, the rate applied will be 22 pounds of dimensional weight if greater than the actual weight.

Common Mistakes To Avoid

To error is human; however, when it comes to business, any mistake can become significantly lethal to the brand. So, to make sure that you are not wrongly measuring the custom boxes, make sure to follow the below-mentioned tips:

- Measuring in the Wrong Order: The standard protocol is to keep your dimensions consistent by measuring length, width, and height. Swapping the axes can be problematic.

- Overlooking Irregular Shapes: For the box with unconventional shapes, describe the maximum of each of the three dimensions.

- Ignoring Internal Dimensions: If you are measuring the inside of the box, you should consider the thickness of the wall, as this may occupy some space.

What Distinguishes Internal And External Dimensions?

Gross dimensions are exterior measurements, while internal dimension refers to the interior space of the box. Some external dimensions are the box wall’s thickness and the overall size.

Conclusion

Following a systematic method, the dimensions must be in the correct format, including length, width, and height, to accurately measure products shipped, stored, or packaged. You can be a storekeeper, a transport manager, or running your own brand; the knowledge of box measurements will go a long way in saving time, costs, and energy.