The term Dieline is important in packaging industries and it plays a pivotal role in making a perfect custom box. But if you do not know about dieline and why it matters in the packaging. Then don’t worry, we have got you covered and discussed everything about Dieline to satiate your curiosity.

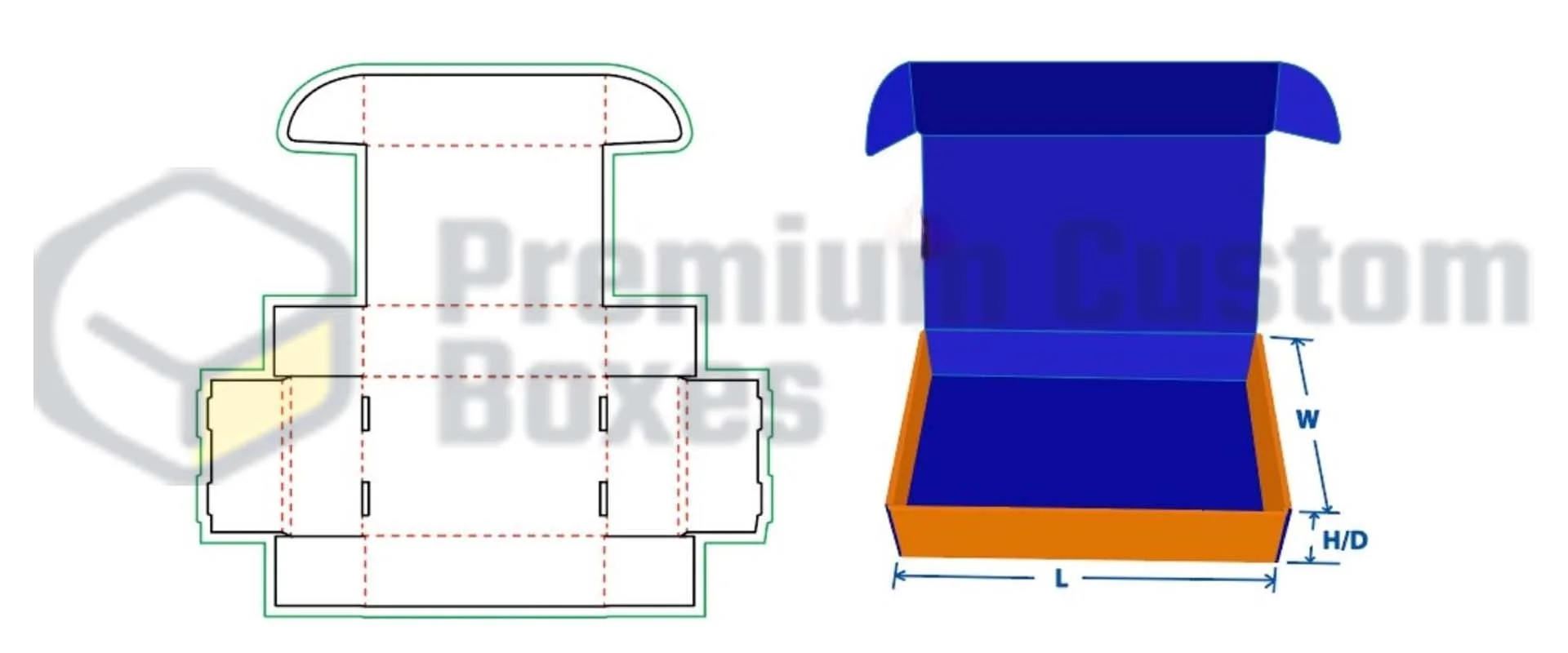

Dieline can be described as an outline of the custom boxes that can be used for the exact printing and packaging of the boxes. This sketch displays all the fold and cut lines of the packaging design in a flattened form. A dieline is digitally designed to get custom packaging boxes and help the printers and die cutters precisely cut, fold and print on your customized boxes.

PremiumCustomBoxes has a highly experienced designer team that can help you with outclass dielines. Let’s jump into the details of this blog.

What is a Dieline?

A Dieline is a blueprint that is used to finalize the layout and the dimensions of the box before sending it for production. Because the final appearance of the customized boxes highly depends on the dieline packaging layout. Even a little difference can ruin the overall packaging.

For a general idea of the cereal box packaging dieline, simply get a custom cereal box and unfold it, then you will see the specific lines displaying the points where the dieline has played its role. Moreover, these dielines are divided into the following line types to let you understand easily.

Fold Lines: These lines show the areas like flaps and where they can be folded from the side, bottom, or top to make the assembly of the box easier.

Perforation lines: The dotted lines that are added to tear any part of the packaging easily.

Cut Lines: The lines that show the specific areas that are needed to be cut down to mold the dieline packaging into an exact given style.

Bleed Line: The bleed line is added to provide additional space in case of any mishap or accidental cutting to cover the damage.

Safety Lines: These are the margins to make sure that the given design including the logo, images, or fonts will not be cut or removed during the cutting and trimming processes.

Glue Tabs: This indicates the area where the adhesive will be applied to assemble the box.

Why Dieline is Important in Packaging?

Dieline is a crucial process in packaging and plays a key role in die cutting processes. Dieline sketch has everything on it including the logo, text, images, fold line, cut line and dimensions. If any of these specifications go wrong then it will automatically end up destroying the final packaging box. So, it is necessary to double-check the packaging dieline before finalizing it for production.

Dieline Requirements for Packaging

A dieline for packaging requires it to be in a vector form because computers understand mathematically described lines. Furthermore, always remember to take accurate specifications while preparing the dieline because even a single error can result in the waste of the efforts of manufacturers, printers or designers. So, add the right specifications before uploading your design document to the software. After this, you can also create a hard copy of your design to avoid any errors before production starts.

Create Dieline for Custom Boxes

A dieline for custom boxes design can be created by graphic designers, die cutters, or professionals of packaging companies. However, you can also make your dieline with a few practices. Simply take a box that can match your required design style, unfold the box and place it flat on the table.

Then note the measurements like length, width, and height, along with materials and styles. This will be the initial procedure of your dieline making. With this procedure, you can also create a dieline for custom retail box packaging.

Besides trying yourself, you can use online design software Adobe Illustrator or Artioscad to make your dieline. Adobe Illustrator includes the following steps in dieline creation.

- First Set up the Adobe Illustrator document page by selecting the CMYK colour mode for the complete design.

- The next step is Dieline Orientation in which you have to make sure that the images and texts face the correct face when they appear on the final packaging box.

- Then remember to keep your artwork like logos, images or texts separate from the dielines. The dielines won’t be printed on the packaging. Also make a separate layer for the finishing or additions like embossing, debossing or foiling to make it easily understandable by the company.

- Place the Bleed lines to avoid any error and label the box’s outside and inside.

- Attach vector-based lines and images. Also outline the text to the document, before sending the design.

- In the last step save your design and send it to the company.

Wrap Up!

Box Dieline is the most important step in packaging and printing because any single error can lead you to start the whole packaging process from scratch. To avoid any misalignment one must make sure to note the accurate specifications. Moreover, premium custom boxes also provide its customers with custom dieline to free them from the hassle of designing of dieline and any possible mistakes. Our expert team has excellent dielines for all kinds of custom boxes design. You can contact us anytime and get our customization services at very reasonable costs.