No Die & Plate Charge

6 Days Turnaround

Free Shipping

FREE Custom Designing

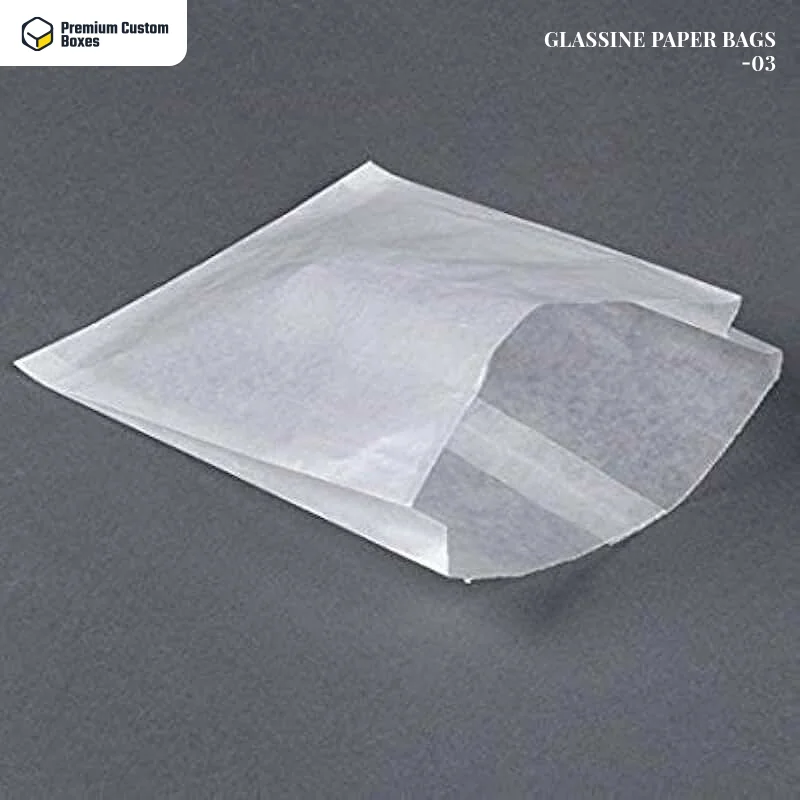

Glassine Paper Bags

Request Custom Quote

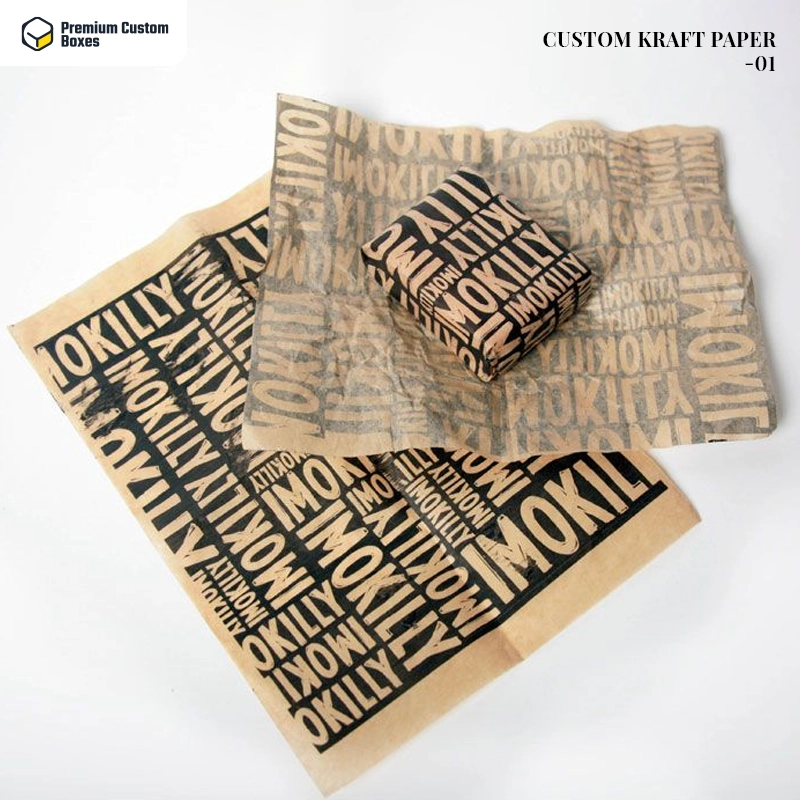

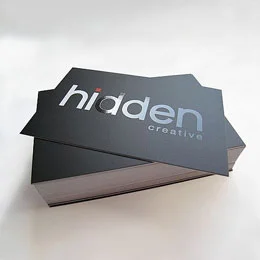

Today sustainable packaging has become popular and versatile options are available for such packaging among them a common option is glassine paper bags. Businesses looking for eco-conscious, elegant, and economical packaging prefer these bags to pack their products. A glassine paper bag is translucent in appearance and has high biodegradability, food, cosmetics, retail, and many other industries can use these bags as an economical alternative to synthetic packaging materials.

Apart from being used as a protective and eco-friendly packaging solution, glassine paper bags with logo allow brands to promote themselves with ease and without spending too much on marketing. By placing your order at our company you can get custom dimension options for your bags and pack your product perfectly.

What Is Glassine Paper?

It is a smooth, glossy, and semi-translucent paper that is manufactured with wood fibres. The wood fibres are processed to remove the airbags to get a smooth surface that is resistant to grease and moisture. This gives transparent glassine paper sheets that are highly durable and a choice for the packaging of perishable items without compromising the look.

Manufacturing Process Of Glassine Paper

In the manufacturing of custom food paper bags, several steps are involved. The first thing that a brand needs to do is to refine the wood pulp and give a translucent surface to the paper. This process focuses on creating a material free from all kinds of pores, with smooth surfaces, and high density that can resist moisture. To manufacture custom glassine food bags paper we follow the below-mentioned steps:

Raw Material

This paper is mainly manufactured with the use of wood pulp that we obtain from softwood trees such as pine and spruce and some hardwood plats such as eucalyptus. After this, the paper is refined extensively so that a smooth and uniform texture can be obtained.

Pulping And Refining

For pulping and refining of sheets for glassine paper bags, we first process the pulp chemically to remove excessive lignin. This process relies on the use of chemicals such as sodium hydroxide and sodium sulphide that help break the wood fibres into cellulose. After pulping, the cellulose fibres are refined again reducing their size and air pocket. This is one of the critical steps as it gives a dense and smooth surface to the paper which is the main character of the paper.

Beating And Pressing

After the pulping and refining, the pulp is beaten mechanically to give it a smooth and dense surface. This step breaks down the fibres and creates a fine slurry of cellulose. No fillers and pigments are added here because we need a clean, transparent, and uncoated paper with a uniform texture. After this pulp is passed to several rollers to compress it and remove excessive water from glassine paper bags wholesale.

Supercalendering

Suprcalendring is the final step in the manufacturing of glassine sheets. Here the paper is heated through smooth rollers that are called calendars under high pressure. This process is the reason for the characteristic gloss and translucent look of the paper. This process also eliminates air pockets left during the first step to give the paper a non-porous, grease-resistant, and moisture-resistant paper.

Custom Printing On Glassine Paper Bags

The option of custom printing facilitates the brands in promoting themselves and showcasing their identity. Custom printed glassine paper bags are available in different designs and logos of your brand so that the uniqueness of your brand remains intact. From our company, you can get simple monochrome logos to multi-colour artwork easily. For the printing of glassine paper, we use digital, scree, flexography, and offset printing. Although many of the printing methods can be used, the best method is flexography because of its high quality and low cost.

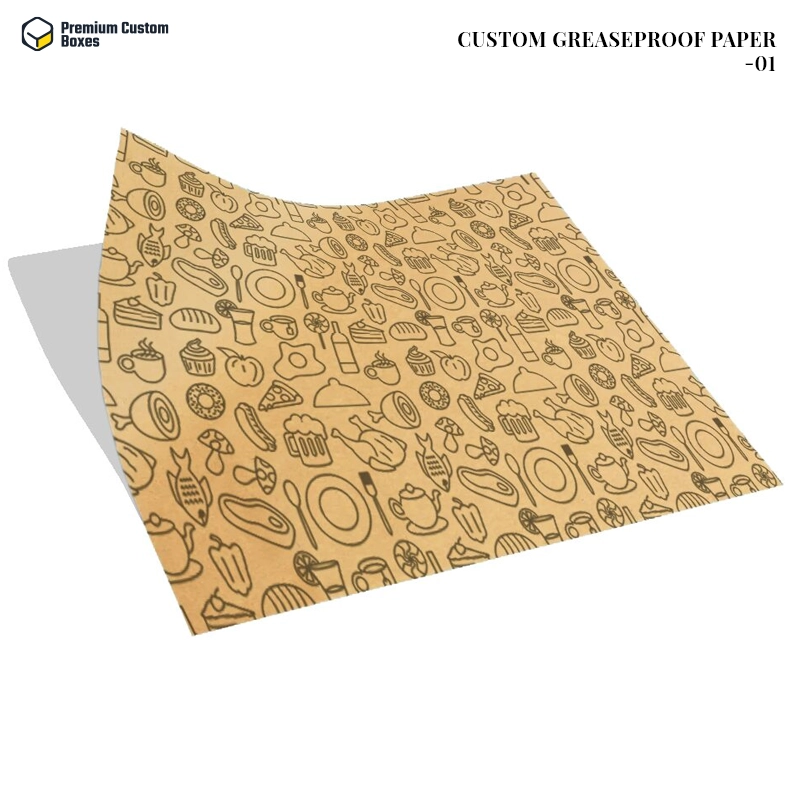

Coatings And Laminations

Additional coatings are applied to enhance the protective ability of the paper so that it can withstand moisture and grease. Like on custom food boxes, the applications of food wraps increase the durability and appearance, some of the coatings that we use on custom food wrapping paper are:

Wax Coating

Wax coatings increase the moisture resistance ability of the paper. It is a useful coating when a brand needs glassine paper-based nags to pack their food products. The best feature of this coating is that it keeps the content fresh for a long period and helps you retain the texture of the food.

Polyethylene Lamination

For added strength and durability, polyethylene coating is the best option. This lamination creates a strong barrier against moisture making it an ideal option for custom-printed glassine paper bags. Food products that need extra protection must be packed in paper laminated with PE coating.

Where to Find Glassine Paper Bags

Businesses seeking glassine paper bags near me, can place their order at our website and get the best experience at the most economical rates. We deal in wholesale rates and give you customized services for all your custom box packaging needs using high-quality and attractive food wrapping paper.

Call Us Now!

Custom glassine paper is among one of the most useful custom food wraps. Its various qualities make it an ideal option for the packaging of food items. By placing your order at PremiumCustomBoxes you can get amazing discounts and remarkable designs with perfect dimensions so place your order now and wrap your food perfectly.

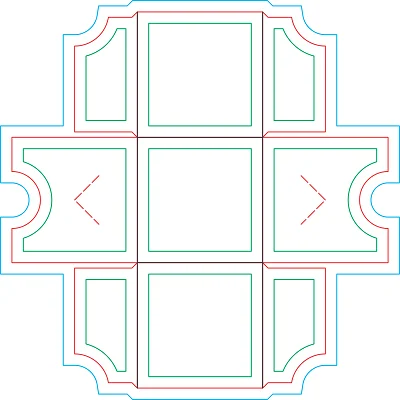

Artwork Preparation Guide

Preparing artwork for various purposes, whether it's for print, digital media, or other applications, requires attention to detail and adherence to specific guidelines. Here is a general artwork preparation guide that you can follow:

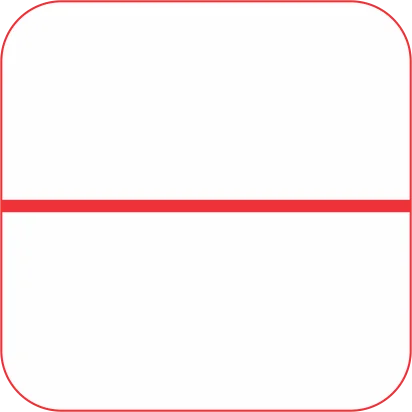

Cutting Line (Red Lines):

Indicates the cut at its final size.Important artwork and text should be placed at least 0.125 inches inside of the cutting line.

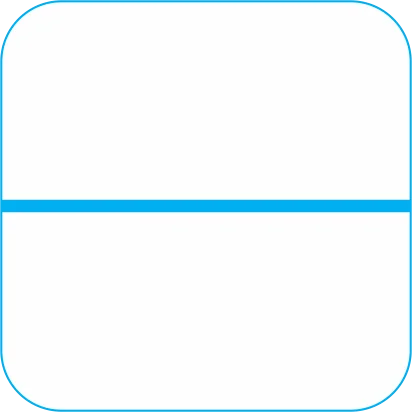

Bleed Area (Blue Lines)

Indicates where the bleed line is located. Any artwork which goes to the cutting line should be extended to the bleed line to get a seamless print.

Safe Area (Green Lines):

Indicates where artwork and text should safely be placed inside. As a industry standard, all artwork should at least be placed 0.125 inches away from the cutting lines unless your design in intentional.

Perforation Lines (Red Lines)

Perforation line refers to paper that is punched with very small holes to allow the paper to be torn and folded easily.

Creasing Line (Black Lines)

Indicated where the product is to be folded.

01

Choose Your Box

Start by browsing our extensive range of box styles and designs. Whether you're in the market for something simple and classic or intricate and bespoke, we've got a multitude of options to suit your needs.

02

Customize the Design

Once you've chosen a box style, it's time to make it uniquely yours. Upload your design or collaborate with our in-house design team to craft a packaging solution that resonates with your brand's aesthetic and vision.

03

Select Materials and Finishes

Our platform allows you to pick from a variety of materials, be it eco-friendly options, premium finishes, or durable structures. Enhance the tactile experience with finishes like matte, gloss, embossing, or specialty textures.

04

Review and Approve

Before we move to production, we'll send you a digital proof or a physical sample upon request. This ensures you're 100% satisfied with the design and materials chosen. Review, make any necessary changes, and give us the green light when you're ready.

05

Production Begins

Once you've approved the design, our team gets to work. With state-of-the-art machinery and a dedicated workforce, we ensure that each box is crafted to perfection, adhering to the highest quality standards.

06

Shipment and Delivery

With our efficient logistics network, we guarantee timely deliveries. As your boxes are packed and prepared for shipment, we'll provide tracking details to keep you informed every step of the way. Sit back and wait for your premium packaging to arrive at your doorstep.

Cardboard

Corrugated

Kraft

Rigid

Anti Scratch Lamination

Aqueous Coating

Lamination

Silk Lamination Cards

Soft Touch Coating

Spot UV

Gloss Lamination

Gloss Varnish

Matt Lamination

Matt Varnish

Debossing

Embossing

Foil stamping

Window Patching

Customer Reviews

Reviews

Great company to work with... my boxes arrived safely.

Excellent product quality and fast delivery. Highly recommended!

Good value for money. The product meets all my expectations.

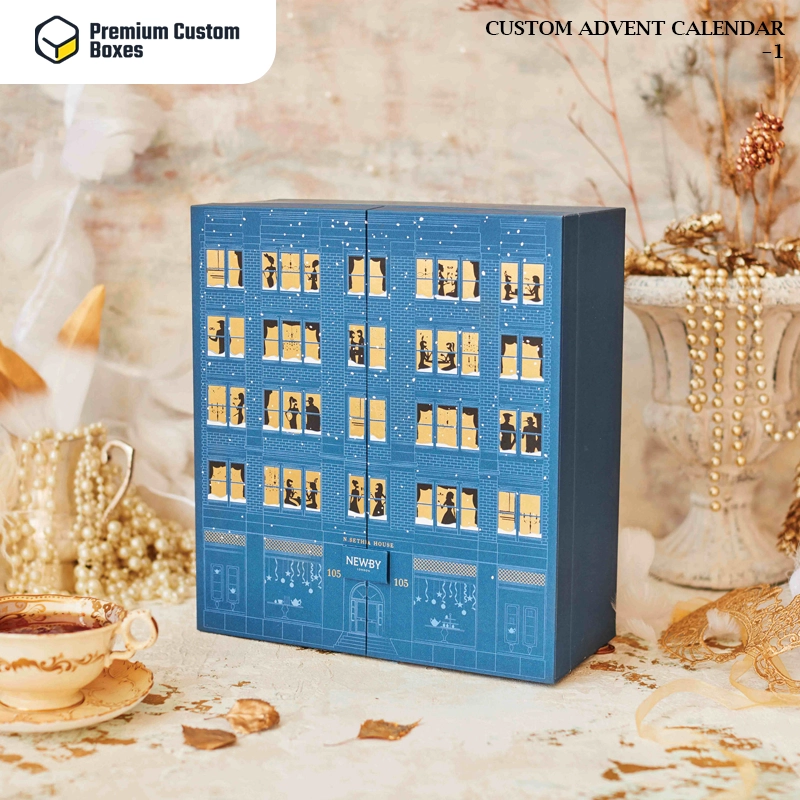

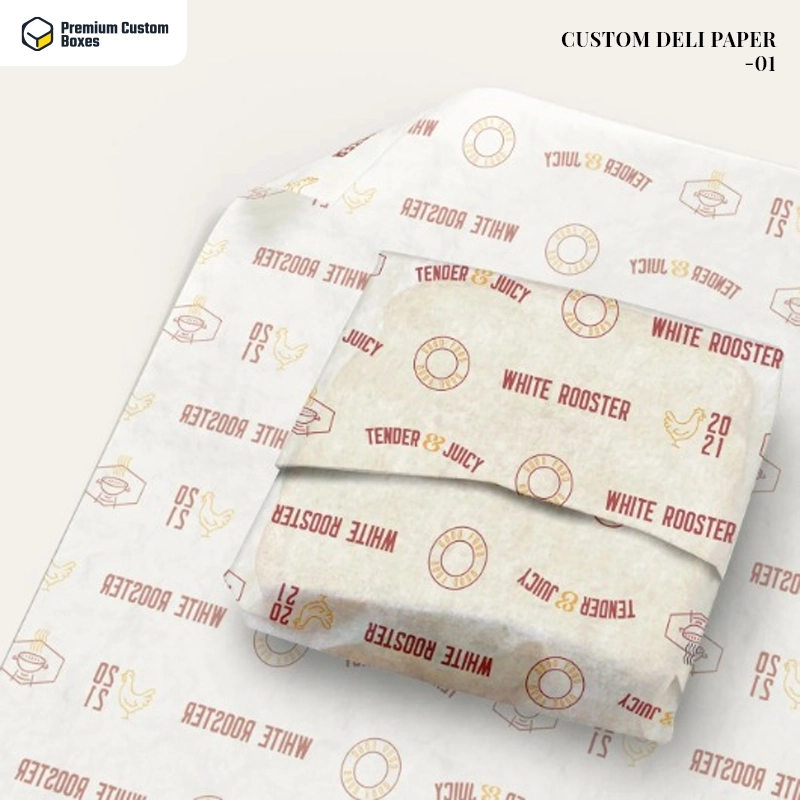

Related Products

Contact Our Customer Care Service

Are you looking forward to investing in our brand but have several concerns? Do you have ambiguity about our custom box services? If yes then you can contact our customer care representative and get all your queries answered in less than a day. Our diligent team is available for your service all around the clock. You can simply fill in the form on the website, email us on the provided email, or you can directly call us at the given number.

Get a Quote Call Us !

Latest Blogs

How Much Is a Pack of Cigarettes in Ontario in 2026?

Smokers and residents in Ontario search for answers to the question “How much does a pack of cigarettes cost?" Ontario...

READ MORE

The Power of Custom Gift Boxes for Valentine’s Day Branding

Many businesses now use smart strategies to stand out in a crowded market. If you want a perfect way to...

READ MORE

7 Best Valentine’s Day Gift Packaging Ideas for Your Loved Ones

Valentine’s Day is not just a couple’s day, but now friends as well celebrate this day to show their love...

READ MORE